All Products

-

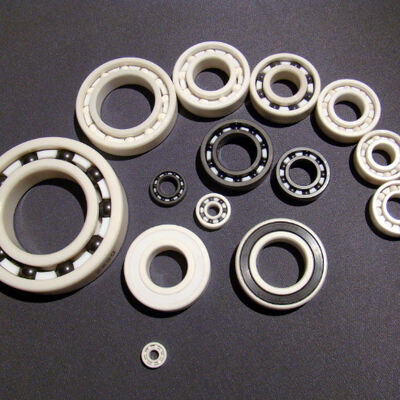

Ceramic Ball Bearings

-

608 Ceramic Bearings

-

Hybrid Ceramic Bearings

-

Silicon Carbide Bearing

-

Ceramic Sliding Bearing

-

Ceramic Roller Bearings

-

Ceramic Thrust Bearing

-

Advanced Structural Ceramics

-

Silicon Nitride Ball

-

Silicon Carbide Ball

-

Zirconia Ceramic Ball

-

Silicon Carbide Ball Bearings

-

Silicon Nitride Ball Bearing

-

Zirconia Ceramic Bearing

-

Mechanical Sealing

-

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years.

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years. -

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Contact Person :

Cooper wang

Phone Number :

86 15801087509

6005 CE ZrO2 Ceramic Ball Bearing with PEEK Cage 25x47x12mm for High-Temperature Applications

Product Details

| Name | 6005ce | Material | ZrO2 Ring, Si3N4 Balls, PTFE Cage |

|---|---|---|---|

| Category | Ceramic Deep Groove Ball Bearing | Temperature | High |

| Designation | 6207: Ø35× Ø47×12mm | Seal Structure | Open |

| Application | Petroleum, Chemical Industry | ||

| Highlight | 35x72x17mm Ceramic Ball Bearing,Non-Magnetic ZrO2 Bearing,Electrically Insulating 6207CE Bearing |

||

Product Description

6005CE ZrO2 Ceramic Ball Bearing with PEEK Cage - 25x47x12mm

Product Overview

The 6005 is a full-ceramic deep groove ball bearing featuring zirconia (ZrO₂) inner and outer rings with silicon nitride (Si₃N₄) balls, combined with a PEEK polymer cage. Engineered with P6-grade precision, this bearing delivers exceptional performance in high-temperature, corrosive, and non-lubricated operating environments.

Key Features & Advantages

- Advanced Materials: Zirconia (ZrO₂) rings and silicon nitride (Si₃N₄) balls provide extreme hardness and superior wear resistance

- High-Performance Cage: PEEK polymer construction offers excellent chemical resistance and lightweight design for high-speed applications

- Precision Engineering: P6 grade accuracy (superior to ABEC-1) ensures low noise operation and smooth rotation

- Corrosion Resistance: Immune to acid and alkali corrosion, making it ideal for cleanroom environments

- Non-Magnetic & Electrically Insulating: Suitable for applications requiring electrical isolation

- Self-Lubricating: Capable of dry-running operation without additional lubrication

Technical Specifications

| Parameter | Value |

|---|---|

| Model | 6005 |

| Dimensions | 25mm × 47mm × 12mm |

| Speed Limit (Grease) | 12,740 rpm |

| Speed Limit (Oil) | 14,300 rpm |

Applications

- Semiconductor manufacturing equipment (vacuum pumps, etching machines)

- Medical devices and instruments (dental drills)

- Chemical processing pumps and systems

- Food processing machinery

- Aerospace testing equipment

Manufacturing Excellence

Professional Expertise

Operating under the ZXSQ and CSQ brands, our company holds eleven utility model invention patents. With a dedicated professional team of dozens of specialists, we provide high-quality customized bearing solutions tailored to specific customer requirements.

Since 1982, we have accumulated over 40 years of manufacturing expertise, continuously advancing ceramic bearing materials research and development while improving processing techniques and production equipment.

Through ongoing evolution and transformation, our company has established itself as a leading enterprise in China's domestic market for ceramic bearings and ceramic material products.

Production Capabilities

We operate a fully automated grinding and assembly production line for ceramic bearings, with an annual production capacity of 3 million sets including 608-2PS, 608-2RS and other specifications in P5 and P4 precision levels.

Our firing equipment and technology lead the industry, featuring the most advanced equipment in domestic industrial ceramics production. This includes a hot isostatic sintering furnace (HIP) imported from ABB Sweden, along with other specialized production equipment capable of reaching firing temperatures exceeding 2000℃.

Frequently Asked Questions

Who are we?

We are a factory based in Beijing, China, with over 40 years of experience in producing and selling ceramic bearings. We have established strong cooperative relationships with numerous domestic and international companies.

How do we guarantee quality?

We conduct sample production before mass manufacturing, strictly adhering to customer specifications and production regulations. Completed products undergo precise inspection using advanced testing equipment. Our packaging utilizes double protection with foam and carton materials to ensure product quality integrity.

What products can you purchase from us?

Ceramic deep groove ball bearings, ceramic angular contact ball bearings, hybrid ceramic ball bearings, ceramic linear bearings, and various types of ceramic balls.

Why choose us over other suppliers?

As an integrated manufacturing and trading company with three production facilities, we utilize modern production and inspection equipment to ensure superior delivery timelines and product quality.

What services do we provide?

We offer high-quality products and comprehensive customization services tailored to user requirements. We provide samples for customer verification and confirmation.

Contact Us for Your Bearing Requirements

We supply premium quality bearing products. For purchasing inquiries or price consultations, please contact our team. As a professional bearing company integrating research and development, production, sales, and service, we provide comprehensive bearing solutions and technical support.

We select superior raw materials and meticulously craft every bearing set. Guided by customer needs, we are committed to providing quality products and exceptional after-sales service, creating value for our clients as trusted partners. We welcome the opportunity to discuss potential cooperation!

Ratings & Review

Recommended Products

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews