-

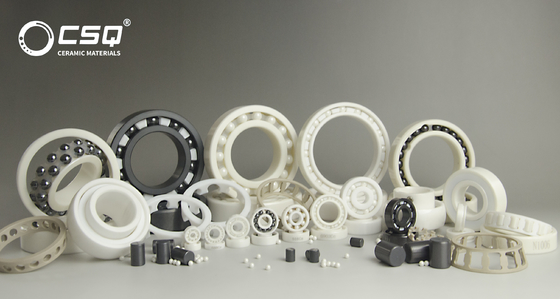

Ceramic Ball Bearings

-

608 Ceramic Bearings

-

Hybrid Ceramic Bearings

-

Silicon Carbide Bearing

-

Ceramic Sliding Bearing

-

Ceramic Roller Bearings

-

Ceramic Thrust Bearing

-

Advanced Structural Ceramics

-

Silicon Nitride Ball

-

Silicon Carbide Ball

-

Zirconia Ceramic Ball

-

Silicon Carbide Ball Bearings

-

Silicon Nitride Ball Bearing

-

Zirconia Ceramic Bearing

-

Mechanical Sealing

-

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years.

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years. -

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Zirconia Oxide Ceramic Ball Bearings Angular Contact Si3N4 SSiC ZrO2 7300 7301 7302

| Name | 7300 Series Ceramic Angular Contact Balls Bearings | Model | 7300 Series |

|---|---|---|---|

| Precision | P6/ABEC3 To P4/ABEC7 | Race And Ball Material | Si3N4/SSiC/ZrO2 |

| Cage Material | Peek/ | MOQ | 50 Pieces |

| Highlight | ceramic zirconia oxide ball bearing,Ceramic Ball Bearings 7300,Ceramic Ball Bearings 7301 |

||

7300 Series Ceramic Angular Contact Balls Bearings In Material Of Si3N4/SSiC/ZrO2

Production technologies of cerami material:

1. Our zirconia material are made by highly purified, sub-micron and after Y2O3-TZP stabled zirconia powder material, are processed by AP (Atmospheric Pressure) sintering and HIP (Hot Isostatic Pressure) sintering technology.

2. Our silicon nitride bearings are made of highly purified, submicron silicon nitride powder with an alpha phase of more than 92%, and is processed by GPS (Gas Pressure) sintering and HIP (Hot Isostatic Pressure) sintering technology.

3. Our silicon carbide bearings are made of highly purified, sub-micron silicon carbide material. The atmospheric pressure solid phase sintering method at a high temperature of 2250°C are used to produce SSiC (Sintering SiC), so the free silicon and free carbon in the products are close to the theoretical values and can resist corrosion of fast all kinds of acid and alkali.

Material properties of ceramic material:

| Material Properties | Units | SSiC | HIP-Si3N4 | GPS-Si3N4 | HIP-ZrO2 |

| Density | g/cm3 | 3.15-3.18 | 3.27-3.29 | 3.22-3.27 | 6.05-6.09 |

| Porosity | % | 0 | 0 | 0 | 0 |

| Fledural Strength | MPa | 550 | 830 | 689 | 900 |

| Elastic Modulus | GPa | 410 | 310 | 310 | 200 |

| Hardness | HV5 | 2800 | 1580 | 1450 | 1300 |

| Fracture Toughness KIC | MPa.m1/2 | 4.6 | 6.1 | 5.7 | 8-11 |

| Maximum Use Temperature |

℃ |

1650 |

1000 |

1000 |

380 |

Reference data of Ceramic Angular Contact Balls Bearings:

| Bearings model |

Form size d (mm) |

Form size D (mm) |

Form size B (mm) |

Load |

Load Cor (N) |

Max.Speed Grease (rpm) |

Max. Speed Oil (rpm) |

| 7300CE | 10 | 35 | 11 | 8340 | 4240 | 39000 | 52000 |

| 7301CE | 12 | 37 | 12 | 10000 | 5030 | 35100 | 45500 |

| 7302CE | 15 | 42 | 13 | 11970 | 6850 | 36400 | 49400 |

| 7303CE | 17 | 47 | 14 | 14130 | 8250 | 33800 | 45500 |

| 7304CE | 20 | 52 | 15 | 16650 | 9950 | 29900 | 40300 |

| 7305CE | 25 | 62 | 17 | 23760 | 15300 | 24700 | 33800 |

| 7306CE | 30 | 72 | 19 | 29250 | 20300 | 20800 | 28600 |

| 7307CE | 35 | 80 | 21 | 36450 | 25800 | 18200 | 24700 |

| 7308CE | 40 | 90 | 23 | 44550 | 32500 | 16900 | 22100 |

| 7309CE | 45 | 100 | 25 | 57600 | 43000 | 14300 | 19500 |

| 7310CE | 50 | 110 | 27 | 67500 | 51500 | 13000 | 18200 |

| 7311CE | 55 | 120 | 29 | 78300 | 60500 | 12220 | 16900 |

| 7312CE | 60 | 130 | 31 | 89100 | 70500 | 11310 | 15600 |

| 7313CE | 65 | 140 | 33 | 100800 | 80500 | 10530 | 14300 |

| 7314CE | 70 | 150 | 35 | 113400 | 92000 | 9750 | 13000 |

![]()

![]()

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews