-

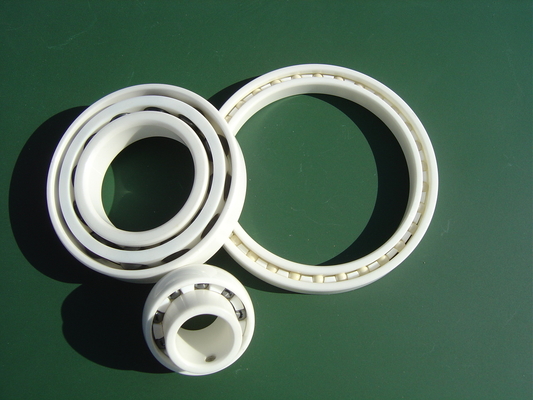

Ceramic Ball Bearings

-

608 Ceramic Bearings

-

Hybrid Ceramic Bearings

-

Silicon Carbide Bearing

-

Ceramic Sliding Bearing

-

Ceramic Roller Bearings

-

Ceramic Thrust Bearing

-

Advanced Structural Ceramics

-

Silicon Nitride Ball

-

Silicon Carbide Ball

-

Zirconia Ceramic Ball

-

Silicon Carbide Ball Bearings

-

Silicon Nitride Ball Bearing

-

Zirconia Ceramic Bearing

-

Mechanical Sealing

-

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years.

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years. -

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

ZrO2 UC205 Ceramic Insert Ball Bearing PTFE Cage With Adapting Thread In Conveyor Systems

| Place of Origin | China |

|---|---|

| Brand Name | CSQ |

| Certification | FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001 |

| Model Number | UC205 |

| Minimum Order Quantity | 50 PCS (negotiable) |

| Price | According to the material and amount. |

| Packaging Details | Foam+carton box |

| Delivery Time | 30-45 works day |

| Payment Terms | T/T or Paypal |

| Supply Ability | 10,000 pcs per month |

| Features | High-Speed, Solid, Light Weight, Flexibility | Name | Ceramic Insert Ball Bearing With Adapting Thread |

|---|---|---|---|

| Material | ZrO2 (Zirconia) / Si3N4 (Silicon Nitride)/ SSiC (Silicon Carbide) | Cage Material | Peek/ Nylon/ PTFE |

| Precision Grades | P6(ABEC3), P5(ABEC5), P4(ABEC7) | Category | Ceramic Ball Bearing |

| Use | Electric Handpieces For Dental | Size | 25×34×52mm |

| Highlight | ZrO2 ceramic ball bearing with PTFE cage,UC205 ceramic insert bearing for conveyor systems,thread adapting ceramic ball bearing with warranty |

||

Product Description of UC205 Ceramic Insert Ball Bearing

The UC205 P6 precision ceramic insert bearing features zirconia (ZrO₂) ceramic inner/outer rings and balls, a PTFE cage, and dual-side seals.

It offers corrosion resistance, high-temperature tolerance, electrical insulation, and lightweight performance, ideal for harsh environments and precision applications.

Key Features

- Full ceramic design (ZrO₂): High hardness (HV≥1200), excellent wear resistance, suitable for corrosive or dry-running conditions.

- PTFE cage: Reduces friction and prevents chemical degradation at high speeds.

- P6 precision grade: Tight tolerances per ISO standards for smooth operation with minimal vibration.

- Dual seals: Protect against contaminants for extended service life.

- Additional benefits: Electrically insulating (no eddy current loss) and 45% lighter than steel bearings.

Technical Specifications

| Material Properties | Units | HIP-ZrO2 |

| Density | g/cm3 | 6.05-6.09 |

| Porosity | % | 0 |

| Fledural Strength | MPa | 900 |

| Elastic Modulus | GPa | 200 |

| Hardness | HV5 | 1300 |

| Fracture Toughness KIC | MPa.m1/2 | 8-11 |

| Maximum Use Temperature |

℃ |

380 |

Reference data of Ceramic Insert Bearings with adapting thread

| Bearings model |

Form size d (mm) |

Form size D (mm) |

Form size B (mm) |

Load |

Load Cor (N) |

Max.Speed Grease (rpm) |

Max. Speed Oil (rpm) |

| UC201CE | 12 | 29 | 47 | 12.7 | 18.3 | 4.5 | M6×0.75 |

| UC202CE | 15 | 29 | 47 | 12.7 | 18.3 | 4.5 | M6×0.75 |

| UC203CE | 17 | 29 | 47 | 12.7 | 18.3 | 4.5 | M6×0.75 |

| UC204CE | 20 | 29 | 47 | 12.7 | 18.3 | 4.5 | M6×0.75 |

| UC205CE | 25 | 34 | 52 | 14.3 | 19.7 | 5 | M6×0.75 |

| UC206CE | 30 | 40.5 | 62 | 15.9 | 22. | 5 | M6×0.75 |

| UC207CE | 35 | 48 | 72 | 17.5 | 25.4 | 6 | M8×1.0 |

| UC208CE | 40 | 53 | 80 | 19 | 30.2 | 8 | M8×1.0 |

| UC209CE | 45 | 57.3 | 85 | 19 | 30.2 | 8 | M8×1.0 |

| UC210CE | 50 | 63 | 90 | 19 | 32.6 | 9 | M10×1.25 |

| UC211CE | 55 | 70 | 100 | 22.2 | 33.4 | 9 | M10×1.25 |

| UC212CE | 60 | 77 | 110 | 25.4 | 39.7 | 10 | M10×1.25 |

| UC213CE | 65 | 82.1 | 120 | 25.4 | 39.7 | 10 | M10×1.25 |

| UC214CE | 70 | 87 | 125 | 30.2 | 44.4 | 12 | M12×1.5 |

| UC215CE | 75 | 91.5 | 130 | 33.3 | 44.5 | 14 | M12×1.5 |

Applications

- Chemical pumps, wastewater systems.

- Food processing, kiln conveyors.

- Medical devices, semiconductor tools.

- Aerospace components, precision instruments.

![]()

![]()

Our Ceramic Ball Bearings are engineered to provide superior performance and reliability in high-speed and high-temperature applications. Our technical support team is available to assist with any questions or issues you may encounter with our product.

We also offer a range of services to ensure the optimal performance of our Ceramic Ball Bearings including installation support, maintenance services, and training programs for your staff. Contact us to learn more about how we can support your business needs.

Packing and Shipping:

Product Packaging:

Our Ceramic Ball Bearings are carefully packaged to ensure their safe delivery to your doorstep. Each bearing is individually wrapped and placed in a sturdy, protective box to prevent any damage during shipping. The box is then sealed and labeled with the product details and shipping information.

Shipping:

We offer worldwide shipping for our Ceramic Ball Bearings. All orders are processed within 1-2 business days and shipped via a reliable courier service. The estimated delivery time varies depending on your location and can range from 3-14 business days. Once your order is shipped, you will receive a tracking number to monitor the progress of your delivery.

FAQ:

Q1: What is the brand name of these ceramic ball bearings?

A1: The brand name of these ceramic ball bearings is CSQ.

Q2: What is the model number of these ceramic ball bearings?

A2: The model number of these ceramic ball bearings is 688 CE.

Q3: Where are these ceramic ball bearings manufactured?

A3: These ceramic ball bearings are manufactured in China.

Q4: What certifications do these ceramic ball bearings have?

A4: These ceramic ball bearings have FDA, REACH, ROHS, ISO9001, ISO14001, and ISO45001 certifications.

Q5: What is the minimum order quantity for these ceramic ball bearings?

A5: The minimum order quantity for these ceramic ball bearings is 50 PCS, but it is negotiable.

Q6: What is the price of these ceramic ball bearings?

A6: The price of these ceramic ball bearings varies according to the material and amount ordered.

Q7: What are the packaging details for these ceramic ball bearings?

A7: The packaging details for these ceramic ball bearings include foam and carton box.

Q8: What is the delivery time for these ceramic ball bearings?

A8: The delivery time for these ceramic ball bearings is between 30 to 45 working days.

Q9: What are the payment terms for these ceramic ball bearings?

A9: The payment terms for these ceramic ball bearings include T/T or Paypal.

Q10: What is the supply ability of these ceramic ball bearings?

A10: The supply ability of these ceramic ball bearings is 10,000 pcs per month.

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews