-

Ceramic Ball Bearings

-

608 Ceramic Bearings

-

Hybrid Ceramic Bearings

-

Ceramic Roller Bearings

-

Ceramic Thrust Bearing

-

Ceramic Sliding Bearing

-

Advanced Structural Ceramics

-

Silicon Nitride Ball

-

Silicon Carbide Ball

-

Zirconia Ceramic Ball

-

Silicon Carbide Ball Bearings

-

Silicon Nitride Ball Bearing

-

Zirconia Ceramic Bearing

-

Mechanical Sealing

-

Silicon Carbide Bearing

-

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years.

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years. -

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

ZrO2 6906ce Ceraminc Ball Bearing

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Ceramic, ZrO2 | Bearing Type | Ceramic Ball Bearing |

|---|---|---|---|

| Percision | P6/ABEC3 To P4/ABEC7 | Characteristic | Long-lasting Life, Low Noise, High Precision |

| Application | Pump | Clearance | C0-C5 |

| Number Of Row | Single Row | Structure | Deep Groove |

| Inner Diameter | 30mm | Out Diameter | 47mm |

| Attribute | Value |

|---|---|

| Material | Ceramic, ZrO2 |

| Bearing Type | Ceramic Ball Bearing |

| Precision | P6/ABEC3 to P4/ABEC7 |

| Characteristic | Long-lasting life, Low noise, High precision |

| Application | Pump |

| Clearance | C0-C5 |

| Number of Row | Single row |

| Structure | Deep groove |

| Inner Diameter | 30mm |

| Out Diameter | 47mm |

Our ceramic bearings feature exceptional properties including high temperature resistance, cold resistance, wear resistance, corrosion resistance, magnetic electrical insulation resistance, oilless self-lubrication, and high-speed performance. These high-tech products are designed for extreme environments and specialized applications across multiple industries.

The rings and rollers utilize premium ceramic materials including zirconia (ZrO2), silicon nitride (Si₃N₄), silicon carbide (SiC), and aluminum oxide (Al₂O₃). Cages are constructed from advanced materials like PTFE, PEEK, UPE, PVDF, PA66, SUS304, and SUS316 for enhanced performance in demanding conditions.

- High Temperature Resistance: Operational range up to 220°C, significantly higher than standard bearings

- High Speed Capability: 1.5 times faster operation than conventional bearings due to low friction coefficient

- Extended Service Life: 2-3 times longer lifespan compared to standard bearings

- Electrical Insulation: Ideal for conductive environments due to ceramic's insulating properties

| Parameter | Description |

|---|---|

| Material | Ceramic: ZrO2 |

| Corrosion resistance | Excellent |

| Friction | Lower than steel |

| Wear resistance | Excellent |

| Temperature resistance | High |

| Strength | Higher than steel |

| Durability | Excellent |

| Weight | Lighter than steel |

| Precision | High |

| Biocompatibility | Some ceramic materials are biocompatible |

- Aviation and aerospace components

- Marine and petroleum equipment

- Chemical processing and automotive systems

- Electronics and power generation

- Medical equipment and research instrumentation

With over 40 years of specialized experience since 1982, we hold eleven utility model patents and maintain a dedicated R&D team focused on ceramic bearing innovation. Our continuous process improvements and equipment upgrades have established us as a market leader in ceramic bearing technology.

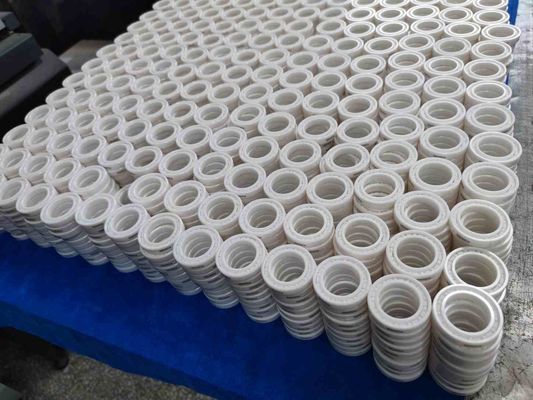

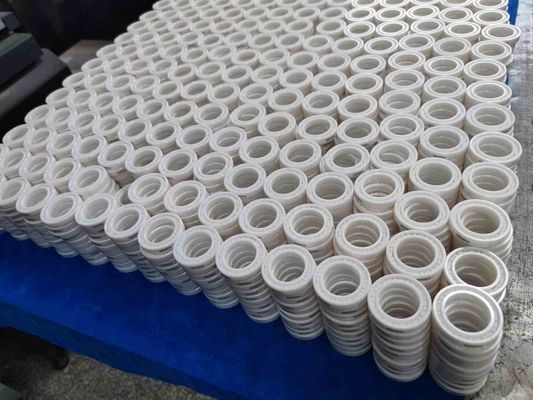

Our fully automated production line delivers 3 million sets annually of P5 and P4 precision bearings. Equipped with industry-leading technology including a Swedish ABB hot isostatic sintering furnace (HIP) capable of reaching 2000℃, we ensure superior product quality and consistency.

We maintain strategic partnerships with raw material suppliers while retaining proprietary production capabilities. This dual approach guarantees stable pricing and uninterrupted supply, unaffected by international market fluctuations.

We are a Beijing-based factory specializing in ceramic bearing production for over 40 years, with established partnerships with domestic and international companies.

Our rigorous process includes pre-production samples, strict adherence to specifications, precision inspection with specialized equipment, and secure double-layer packaging.

Our portfolio includes ceramic deep groove ball bearings, angular contact bearings, hybrid bearings, linear bearings, and various ceramic ball components.

As an integrated manufacturer with three production facilities, we combine advanced equipment with extensive expertise to deliver superior quality and reliable lead times.

We offer comprehensive customization, sample confirmation, and technical support to meet specific application requirements.

We provide premium bearing solutions with comprehensive technical support. Our commitment to quality begins with material selection and extends through every production stage. Partner with us for customized bearing solutions tailored to your specific requirements.

Contact our team today to discuss your project needs or request product samples.