-

Ceramic Ball Bearings

-

608 Ceramic Bearings

-

Hybrid Ceramic Bearings

-

Silicon Carbide Bearing

-

Ceramic Sliding Bearing

-

Ceramic Roller Bearings

-

Ceramic Thrust Bearing

-

Advanced Structural Ceramics

-

Silicon Nitride Ball

-

Silicon Carbide Ball

-

Zirconia Ceramic Ball

-

Silicon Carbide Ball Bearings

-

Silicon Nitride Ball Bearing

-

Zirconia Ceramic Bearing

-

Mechanical Sealing

-

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years.

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years. -

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Miniature 695 / 623 Ceramic Ball Bearings For Autonomous Underwater Vehicle

| Place of Origin | China |

|---|---|

| Brand Name | CSQ |

| Certification | FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001 |

| Model Number | 695 / 623 Miniature Bearings |

| Minimum Order Quantity | 100 PCS |

| Price | According to the materials, quantity and others |

| Packaging Details | Foam+carton box |

| Delivery Time | 20-35 work days |

| Payment Terms | T/T or Paypal |

| Supply Ability | 10,000 pcs per month |

| Features | Excellent Corrosion Resistance, Friction Resistance, Temperature Stability | Name | Miniature Ceramic Bearings For Autonomous Underwater Vehicle |

|---|---|---|---|

| Category | Ceramic Ball Bearings | Material | Zirconia, Silicon Carbide, Silicon Nitride |

| Ring | Zirconia, Silicon Carbide, Silicon Nitride | Cage | PEEK/ Nylon/ PTFE |

| Certification | FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001 | Precision Grade | P6 (ABEC3), P5 (ABEC5), P4(ABEC7) |

| Ball | Zirconia, Silicon Nitride, Silicon Carbide | Grade Of Ball | G3 - G10 |

| Sealing | Single Or Double PEEK, PTFE Sealed | Application | AUV (Autonomous Underwater Vehicle) |

| Highlight | autonomous underwater vehicle ceramic ball bearings,695 ceramic ball bearings,miniature 623 ceramic bearing |

||

The Brief Introduction of CSQ Ceramic Ball Bearings

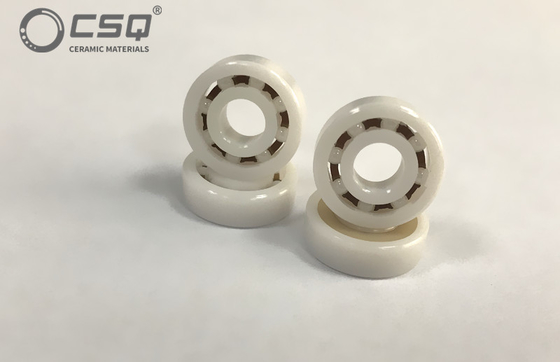

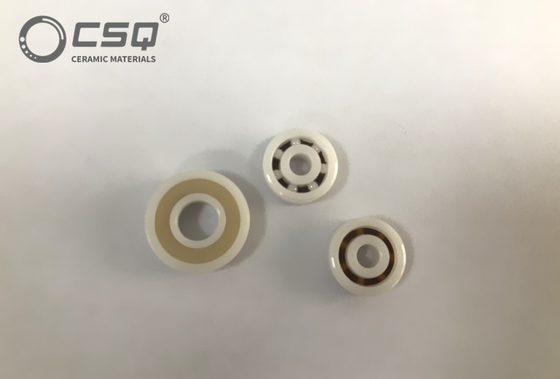

The below photo is our miniature ceramic bearings of 693 and 695. Our factory produces three materials, they are silicon nitride, silicon carbide and zieconia, you can choose one of them you want. And about the ring, we recommend you the ceramic inner ring and outer ring. About the ball, you can also choose zirconia, silicon nitride and silicon carbide. For the cage, we have PTFE, Nylon and PEEK, but you can also choose other materials. The precision grade of bearings is high up to P4 ( ABEC7 ). About sealing, you can choose sealed or open. If you choose sealing, we have PEEK, PTFE, Rubber or others you want. Other details of products, please see the below photo. If you want to know more, welcome email me~

![]()

(The photo is about miniature ceramic bearings of 693 and 695.)

Corrosion Resistance and Temperature Stability for AUV

Miniature ceramic bearings can be used in various parts of Autonomous Underwater Vehicles, such as pressing housings, sensors and transducers, electrical connectors, heat exchangers and other parts.

And if you use our miniature ceramic ball bearings, you will get :

1. Corrosion resistance: AUVs operate in highly corrosive marine environments with exposure to saltwater. Ceramic bearings have excellent corrosion resistance, making them ideal for use in AUVs. They can withstand prolonged exposure to saltwater without deteriorating or rusting, ensuring the longevity and reliability of the bearings, that means less maintenance and long service life.

2. High hardness and wear resistance: Ceramic materials, such as silicon nitride or zirconia, used in ceramic bearings exhibit high hardness and exceptional wear resistance. This property is particularly beneficial in AUV applications where the bearings are subjected to high loads and rotational speeds. Ceramic bearings can withstand these demanding conditions without significant wear, resulting in extended bearing life and reduced maintenance requirements.

3. Low friction and high efficiency: Ceramic bearings have lower friction coefficients compared to metal bearings. This characteristic reduces energy losses due to friction, resulting in improved overall efficiency of AUV propulsion systems. The reduced friction also enables smoother operation and reduces heat generation, contributing to enhanced performance and thermal management in AUVs.

4. Reduced noise and vibration: Ceramic bearings exhibit lower levels of noise and vibration compared to metal bearings. This characteristic is desirable in AUVs as it helps minimize acoustic signatures and disturbances, allowing for quieter and less disruptive underwater operations.

![]()

(The photo of Autonomous Underwater Vehicle is from the Internet)

CSQ that Contains Industry and Trade

Our company is specialized in producing ceramic balls and ceramic bearings, the technology is inherited from the parent company: Beijing Zhongxing Shiqiang Ceramic Bearing Company, which already has FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001 certifications.

![]()

Now I will introduce the Tianjin branch, the factory covers an area of about 4000 square meters, equipped with automatic production and assembly line, ball grinding machine and other production equipment, as well as a variety of bearing testing equipment. We have professional testing equipment and technicians. All products are 100% strictly inspected before exporting, including appearance defect inspection, roundness, roughness and geometry size, and all products meet ISO international standards.

![]()

![]()

At present, our company mainly produces ceramic ball bearings, sliding bearings, ceramic balls and ceramic industrial parts. The production materials are high performance ceramic materials, mainly SSIC, Si3N4 and ZrO2 material. And we have a series of professional production and inspection equipments, such as the HIP (High temperature Insostatic Pressing) Equipment is from ABB Sweden, the inspection equipments are mostly from Mitutoty. The products will be strictly 100% inspected before export.

Our main customers are mainly located in Germany, United Kingdom and other European countries and Japan, Korea and other Asian countries. We dedicate to provide high level products and technical services, our experienced and professional team is committed to handling your enquiry quickly and accurately.

We are looking forward to your enquiry!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews