-

Ceramic Ball Bearings

-

608 Ceramic Bearings

-

Hybrid Ceramic Bearings

-

Silicon Carbide Bearing

-

Ceramic Sliding Bearing

-

Ceramic Roller Bearings

-

Ceramic Thrust Bearing

-

Advanced Structural Ceramics

-

Silicon Nitride Ball

-

Silicon Carbide Ball

-

Zirconia Ceramic Ball

-

Silicon Carbide Ball Bearings

-

Silicon Nitride Ball Bearing

-

Zirconia Ceramic Bearing

-

Mechanical Sealing

-

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years.

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years. -

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

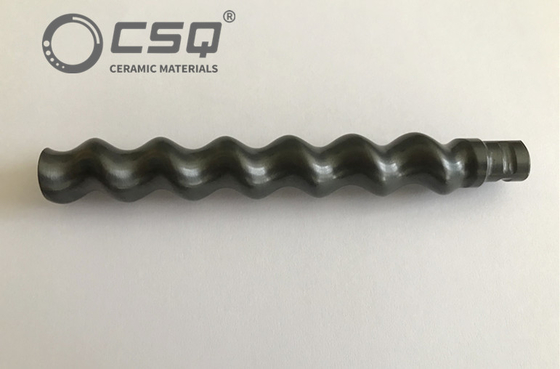

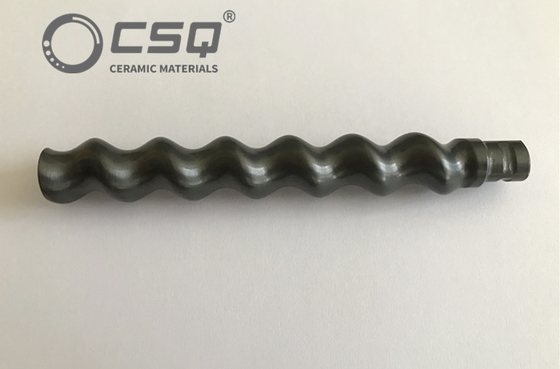

Wear Resistance Ceramic Screw For Mud / Oil Transmit Industry

| Place of Origin | China |

|---|---|

| Brand Name | CSQ |

| Certification | FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001 |

| Model Number | Customized |

| Minimum Order Quantity | One piece |

| Price | Negotiable, according to the customers' drawings |

| Packaging Details | Foam+carton box |

| Delivery Time | About 30 work days |

| Payment Terms | T/T, Paypal |

| Supply Ability | 1000 pieces per month |

| Name | Silicon Carbide / Zirconia Ceramic Screw | Category | Advanced Structural Ceramics |

|---|---|---|---|

| Material | Silicon Carbide / Zirconia | Corrosion Resistance | High |

| Abrasion Resistance | Excellent | Density | High |

| Feature | Superior Quality, Wear Resistance | Application | Pump Mud / Oil Transmit Mechanical |

| Brand | CSQ | OEM Or ODM | OEM |

| Highlight | wear resistance ceramic screw,oil transmit industry ceramic screw,mud ceramic fasteners |

||

Product Description:

The Brief Introduction of Ceramic Screw

Ceramic Screws are high-performance structural ceramics designed for long-term use in extremely corrosive and abrasive environments. They are made of advanced ceramic structures, including silicon carbide and zirconia, offering superior corrosion resistance, abrasion resistance, and wear resistance. This makes them ideal for applications such as glue dispensers and material transportation.

![]()

You can see in the picture. It's a ceramic screw made of silicon carbide. The size is about 4 cm, our factories can also produce other sizes, but we need your drawings or you tell us what size you want. More importantly, a series of processes from raw materials to pressing, sintering, products, inspection and trade are all done independently by our factory. So we have CONFIDENT that you will be satisfied with our products.

Technical Parameters:

| Parameter | Value |

|---|---|

| Name | Silicon Carbide Ceramic Screw Shaft |

| Density | High |

| Corrosion Resistance | High |

| Category | Advanced Structural Ceramics |

| Feature | Famous Brand, Superior Quality |

| Wear Resistance | High |

| Application | Glue Dispenser / Material Transportation |

| Chemical Resistance | High |

| Material | Silicon Carbide / Zirconia |

| Abrasion Resistance | High |

| Advanced Ceramic Technologies | Yes |

| Advanced Ceramic Structures | Yes |

Applications:

•Pump Mud Transmit Mechanical

![]()

•Pump Oil Transmit Mechanical

![]()

►Wear Resistance: Mud often contains abrasive particles that can cause significant wear on metal components. Ceramic screws, on the other hand, offer excellent wear resistance, making them suitable for handling abrasive fluids like mud. Their hardness and resistance to abrasion allow them to maintain their integrity and functionality over an extended period.

►High Strength: Ceramic screws can exhibit high tensile strength and mechanical stability, even under high-pressure conditions. This is important in pump applications where the screws need to withstand the forces generated by the pumping action and the weight of the fluid being transported. The high strength of ceramic screws allows them to handle the mechanical stresses and pressures associated with pumping mud.

►Non-Magnetic Properties: In some applications, such as in the oil and gas industry, it is crucial to avoid the presence of magnetic materials that can interfere with sensitive equipment. Ceramic screws are non-magnetic, which makes them suitable for use in such environments where magnetic interference needs to be minimized.

Support and Services:

Advanced Structural Ceramics is committed to providing the highest level of product support and service. Our experienced team of professionals are dedicated to addressing your inquiries quickly and accurately.

We provide technical support and services for Advanced Structural Ceramics products, including:

- Product troubleshooting and repair

- Product customization and optimization

- Product upgrades and updates

We also provide support for warranty claims and product returns. If you have any questions or need assistance, please contact us.

About our comapny-ZXSQ

►Certifications

![]()

►Production lines and inspection equipments

![]()

FAQ:

1. Q:What the MQQ of your company?

A:MQQ is 20-50 pcs.

2. Q:Could you accept OEM and customize?

A:YES,we can customize according to your sample or drawing.

3. Q:Could you supply sample for free?

A:Yes,we can supply sample for free, but not charge the freight.

4. Q:Does your factory have any certificate?

A:yes.we have FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001.

5. Q:IS you company factory or Trade Company?

A:We are the supplier and we have our own factory.

6. Q:Could you tell me the material of our bearing?

A:We have ZrO2(Zirconia), Silicon Carbide(SSiC), Silicon Nitride(Si3N4), Aluminia(Al2O3).

7. Q:Could you offer door to door service?

A:Yes,by express(DHL,FEDEX,TNT,UPS.)

8. Q:Could you tell me the payment term of your company can accept?

A:T/T or Paypal.

9. Q:Your factory how to control the quality?

A: All bearing parts before the production and the production process, strict inspection by 100%, including crack detection, roundness, hardness, roughness, and the geometry size, all bearing meet ISO international standard.

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews