-

Ceramic Ball Bearings

-

608 Ceramic Bearings

-

Hybrid Ceramic Bearings

-

Silicon Carbide Bearing

-

Ceramic Sliding Bearing

-

Ceramic Roller Bearings

-

Ceramic Thrust Bearing

-

Advanced Structural Ceramics

-

Silicon Nitride Ball

-

Silicon Carbide Ball

-

Zirconia Ceramic Ball

-

Silicon Carbide Ball Bearings

-

Silicon Nitride Ball Bearing

-

Zirconia Ceramic Bearing

-

Mechanical Sealing

-

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years.

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years. -

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

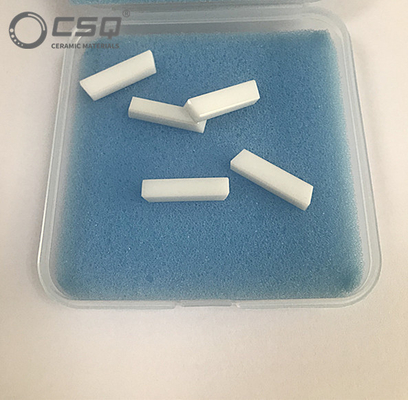

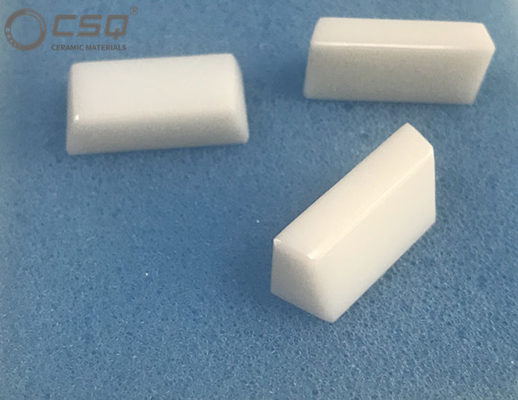

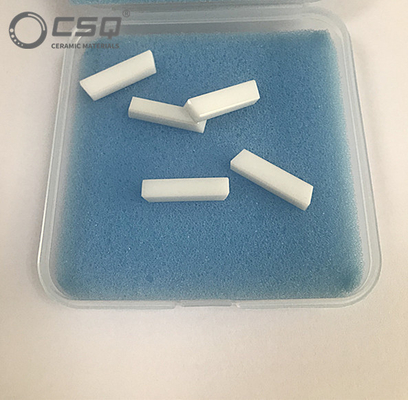

Zro2 Ceramics Fulcrum , Zirconia Clamping Plate Customization

| Place of Origin | China |

|---|---|

| Brand Name | CSQ |

| Certification | FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001 |

| Model Number | Customization |

| Minimum Order Quantity | 50-100 pcs |

| Price | Negotiable |

| Packaging Details | Small Plastic Square Box + Sponge + Foam + Carton Box |

| Delivery Time | 25-40 work days |

| Payment Terms | T/T , Paypal |

| Supply Ability | 20,000 pcs per month |

| Name | ZrO2 Ceramics Fulcrum, Zirconia Ceramics Clamping Plate | Category | Advanced Structural Ceramics |

|---|---|---|---|

| Material | Zirconia (ZrO2) | Size | Customization, According To The Drawings. |

| Keywords | Smooth And Precise Movement, Biocompatibility | Grade | Customization, According To The Drawings. |

| Characteristic | High Density, Smooth Surface, Hardness | Application/ Use | Precision Engineering |

| Highlight | zro2 ceramic clamps,customization ceramic clamps |

||

zro2 ceramics fulcrum, high-performance components for precision engineering, zirconia clamping plate

The Brief Introduction of ZrO2 Fulcrm, Clamping Plate

The ZrO2 ceramic fulcrum is a pivot point or support made from zirconia ceramic material (ZrO2). Zirconia is a type of ceramic that is known for its exceptional mechanical properties, including high strength, toughness, and wear-resistance. These qualities make it an excellent material for use in fulcrums and other precision components.

In addition to its mechanical properties, zirconia also has other advantages that make it attractive for use in fulcrums. For example, it is highly biocompatible, which means it is well-suited for use in medical devices that come into contact with the human body. It is also chemically inert, which makes it resistant to chemical attack and corrosion.

The use of zirconia ceramic fulcrums offers several advantages over other materials, such as metals or plastics. Zirconia is highly resistant to wear and corrosion, which means that it can maintain its shape and function over time, even under harsh conditions. It is also very hard and has a low coefficient of friction, which allows for smooth and precise movement.

![]()

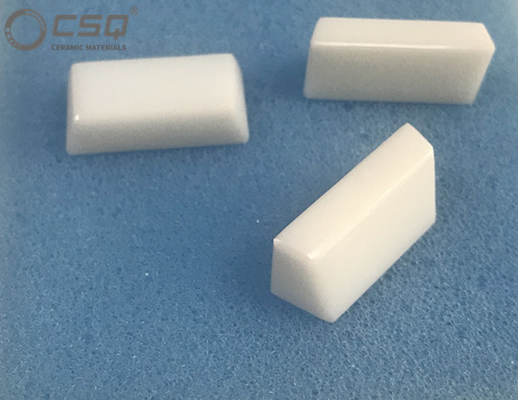

The Characteristics and Advantages of ZrO2 Fulcrm

►Design flexibility: ZrO2 fulcrums can be designed to meet specific requirements, including size, shape, and load capacity. This design flexibility makes them suitable for a wide range of applications.

►Low coefficient of friction: Zirconia has a low coefficient of friction, which means that it can slide or rotate smoothly against other materials without generating excessive friction or heat.

►Hardness: Zirconia is also a very hard material, with a high resistance to wear and abrasion. This makes it an ideal material for use in fulcrums that are subjected to friction and constant movement.

►Biocompatibility: Zirconia is biocompatible, which means that it is well-suited for use in medical devices that come into contact with the human body.

![]()

The Applications of ZrO2 Fulcrm--Precision Engineering

ZrO2 fulcrums are used in precision engineering applications such as scanning probe microscopes, atomic force microscopes, and other high-precision instruments. Their low coefficient of friction, high strength, and durability make them ideal for use in these applications, where accuracy and stability are critical.

Here are some ways in which ZrO2 fulcrums can be used in precision engineering:

1. Sliding movement: ZrO2 fulcrums can be used to provide smooth and precise sliding movement of mechanical components, such as in linear stages or sliding mechanisms.

2. Rotational movement: ZrO2 fulcrums can be used to provide precise and stable rotational movement of mechanical components, such as in rotary stages or bearings.

3. Oscillatory movement: ZrO2 fulcrums can be used to provide stable and precise oscillatory movement of mechanical components, such as in scanning probe microscopes or atomic force microscopes.

![]()

Overall, the unique combination of properties offered by ZrO2 fulcrums makes them an attractive choice for use in precision engineering applications where high accuracy, stability, and durability are required.

An Overall Introduction of Our Company and Factory--ZXSQ

►The Certifications of ISO45001, ISO14001, ISO9001

![]()

►The Production Lines and Inspection Equipments

![]()

![]()

We have three factories in China, can meet the needs for different customers, and also we have advanced pressing, sintering and processing machines. Our company has specialized production of high-precision ceramic ball production line, as well as ceramic bearing grinder, automatic assembly production line. In addition, our HIP sintering furnace from Sweden ABB company, so we are confident that you will be satisfied with our products.

With over 20 years of ceramic producing experience, we are fully equipped to answer any questions you have. Give us a call or send us a message today, and we will contact with you.

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews