-

Ceramic Ball Bearings

-

608 Ceramic Bearings

-

Hybrid Ceramic Bearings

-

Silicon Carbide Bearing

-

Ceramic Sliding Bearing

-

Ceramic Roller Bearings

-

Ceramic Thrust Bearing

-

Advanced Structural Ceramics

-

Silicon Nitride Ball

-

Silicon Carbide Ball

-

Zirconia Ceramic Ball

-

Silicon Carbide Ball Bearings

-

Silicon Nitride Ball Bearing

-

Zirconia Ceramic Bearing

-

Mechanical Sealing

-

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years.

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years. -

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

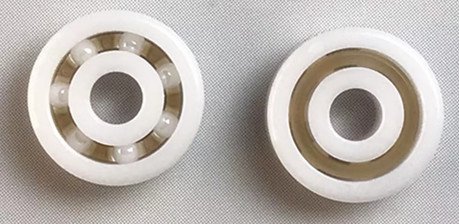

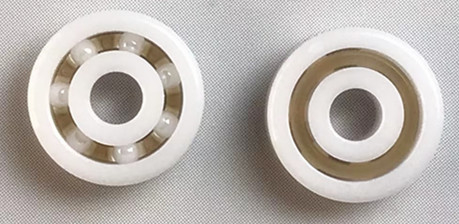

623ce Miniature Ceramic Rolling Zro2 Bearing For Special Working Conditions

| Place of Origin | Tianjin, China |

|---|---|

| Brand Name | CSQ |

| Certification | FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001 |

| Model Number | 623CE |

| Minimum Order Quantity | 20-50 pcs (negotiable) |

| Price | negotiable |

| Packaging Details | Foam+carton box |

| Delivery Time | 20-45 work days(negtiable) |

| Payment Terms | T/T |

| Supply Ability | 2000 pcs per month |

| Size | 3 X 10 X 4 | Ball | 1.588 |

|---|---|---|---|

| Cage | Nylon/Peek | Precision Grade | P6/ABEC3 To P4/ABEC7 |

| Feature | High Temperature Resistance, Wear Resistance | Application | Construction Machinery (special Working Conditions) |

| Highlight | 623ce zro2 bearing,special working conditions zro2 bearing |

||

623ce Zirconia Bearings of ZrO2 Races/Balls+PEEK Cage with P6/ABEC3-P4/ABEC7 Precision

Description of 115ce All Zirconia Miniarure Bearings (Zirconia+PEEK):

•ZrO2 races and balls: are processed by AP (Atmospheric Pressure) sintering and HIP (Hot Isostatic Pressure) sintering technology, so their porosity, wear resistance, impact resistance and resistance to fatigue contact life are greatly improved.

•PEEK cage: The crown structure cages are adopted British Victrex PEEK material and injection molded at high temperature, so have high strength, light body, and will be fitted to the bearings using our unique design of press-fit double-sided construction.

A kind of special bearings through full grinding, with high precision and a variety of excellent performance, has a density and linear expansion coefficient close to that of metal steel shafts, high hardness Hv1280, wear resistance, resistance to various strong acids, strong alkalis, salt corrosion (except hydrofluoric acid), non-magnetic, non-conductive, high temperature resistance, high operating speed, impact resistance, small starting torque, resistance to dry friction, is one of the most widely used ceramic bearings.

| ►Key properties of zirconia |

| ♦ Max Temperature up to 380℃ |

| ♦ High density: 6.09 g/cm3 |

| ♦ Low thermal conductivity |

| ♦ Chemical stability, resistance to acid and alkali corrosion |

| ♦ High fracture toughness KIC:8-11 MPa-m1/2 |

| ♦ Good electric insulation |

| ♦ Better bearing capacity |

| ♦ Wear resistance |

| ♦ High hardness : 1300 HV5 |

![]()

623ce Applications--Construction machinery, extremely harsh environment and special working conditions

![]()

![]()

Our Factory

•Certifications

![]()

•Production Lines and Inspection Equipment

![]()

•Why choose us

We have three factories in China, can meet the needs for different customers, and also we have advanced pressing, sintering and processing machines. Our company has specialized production of high-precision ceramic ball production line, as well as ceramic bearing grinder, automatic assembly production line. In addition, our HIP sintering furnace from Sweden ABB company, so we are confident that you will be satisfied with our products.

![]()

![]()

•FAQ

1. Q:What the MQQ of your company?

A:MQQ is 20-50 pcs.

2. Q:Could you accept OEM and customize?

A:YES,we can customize according to your sample or drawing.

3. Q:Could you supply sample for free?

A:Yes,we can supply sample for free, but not charge the freight.

4. Q:Does your factory have any certificate?

A:yes.we have FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001.

5. Q:IS you company factory or Trade Company?

A:We are the supplier and we have our own factory.

6. Q:Could you tell me the material of our bearing?

A:We have ZrO2(Zirconia), Silicon Carbide(SSiC), Silicon Nitride(Si3N4), Aluminia(Al2O3).

7. Q:Could you offer door to door service?

A:Yes,by express(DHL,FEDEX,TNT,UPS.)

8. Q:Could you tell me the payment term of your company can accept?

A:T/T.

9. Q:Your factory how to control the quality?

A: All bearing parts before the production and the production process, strict inspection by 100%, including crack detection, roundness, hardness, roughness, and the geometry size, all bearing meet ISO international standard.

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews