-

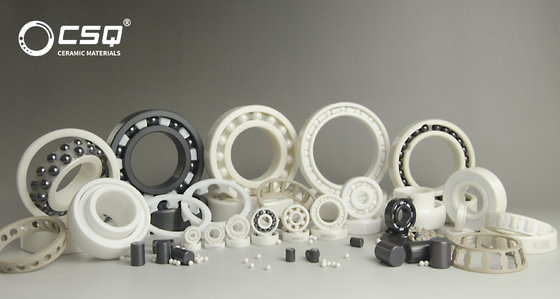

Ceramic Ball Bearings

-

608 Ceramic Bearings

-

Hybrid Ceramic Bearings

-

Silicon Carbide Bearing

-

Ceramic Sliding Bearing

-

Ceramic Roller Bearings

-

Ceramic Thrust Bearing

-

Advanced Structural Ceramics

-

Silicon Nitride Ball

-

Silicon Carbide Ball

-

Zirconia Ceramic Ball

-

Silicon Carbide Ball Bearings

-

Silicon Nitride Ball Bearing

-

Zirconia Ceramic Bearing

-

Mechanical Sealing

-

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years.

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years. -

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Si3N4 SSiC Zro2 Ceramic Bearing Durability High 61800 61801 61802 Extra Thin

| Name | 61800 Series Extra Thin Type Ceramic Balls Bearings | Model | 61800 Series (6800 Series) |

|---|---|---|---|

| Race And Ball Material | Si3N4/SSiC/ZrO2 | Cage Material | Peek//Nylon/PFA |

| Precision | P6/ABEC3 To P4/ABEC7 | Pacage | Foam+cartom Box |

| Highlight | ball bearing 61802,61801 ball bearing,61800 bearing |

||

61800 Series Extra Thin Type Ceramic Balls Bearings In Material Of Si3N4/SSiC/ZrO2

Description of Extra Thin Type Ceramic Deep Groove Bearings:

The material of races and balls can be chosen among silicon nitride, silicon carbide and zirconia. SSiC material has best corrosion resistance, Si3N4 material is the most light and has excellent magnetic and electrical insulation, ZrO2 material has the best wear resistance.

Material properties of our ceramic material:

| Material Properties | Units | SSiC | HIP-Si3N4 | GPS-Si3N4 | HIP-ZrO2 |

| Density | g/cm3 | 3.15-3.18 | 3.27-3.29 | 3.22-3.27 | 6.05-6.09 |

| Porosity | % | 0 | 0 | 0 | 0 |

| Fledural Strength | MPa | 550 | 830 | 689 | 900 |

| Elastic Modulus | GPa | 410 | 310 | 310 | 200 |

| Hardness | HV5 | 2800 | 1580 | 1450 | 1300 |

| Fracture Toughness KIC | MPa.m1/2 | 4.6 | 6.1 | 5.7 | 8-11 |

| Maximum Use Temperature |

℃ |

1650 |

1000 |

1000 |

380 |

Reference data of Extra Thin Type Ceramic Deep Groove Bearings:

| Bearings model |

Form size d (mm) |

Form size D (mm) |

Form size B (mm) |

Load |

Load Cor (N) |

Max.Speed Grease (rpm) |

Max. Speed Oil (rpm) |

| 61800CE | 10 | 19 | 5 | 1590 | 985 | 37000 | 48400 |

| 61801CE | 12 | 21 | 5 | 1440 | 1040 | 32000 | 42900 |

| 61802CE | 15 | 24 | 5 | 1560 | 1260 | 28000 | 37400 |

| 61803CE | 17 | 26 | 5 | 1973 | 1570 | 26000 | 33000 |

| 61804CE | 20 | 32 | 7 | 3000 | 2640 | 22000 | 28600 |

| 61805CE | 25 | 37 | 7 | 3225 | 2940 | 18000 | 24200 |

| 61806CE | 30 | 42 | 7 | 4013 | 3800 | 15000 | 19800 |

| 61807CE | 35 | 47 | 7 | 3563 | 3800 | 14000 | 17600 |

| 61808CE | 40 | 52 | 7 | 4463 | 4900 | 12000 | 15400 |

| 61809CE | 45 | 58 | 7 | 4013 | 4900 | 11000 | 14300 |

| 61810CE | 50 | 65 | 7 | 4800 | 5800 | 10000 | 13200 |

| 61811CE | 55 | 72 | 9 | 6600 | 8100 | 8700 | 11000 |

| 61812CE | 60 | 78 | 10 | 8625 | 10600 | 8000 | 10450 |

| 61813CE | 65 | 85 | 10 | 8925 | 11500 | 7500 | 9570 |

| 61814CE | 70 | 90 | 10 | 9075 | 11900 | 7000 | 8910 |

| 61815CE | 75 | 95 | 10 | 9375 | 12800 | 6500 | 8360 |

| 61816CE | 80 | 100 | 10 | 9525 | 13300 | 6000 | 7810 |

| 61817CE | 85 | 110 | 13 | 14025 | 19000 | 5700 | 7370 |

| 61818CE | 90 | 115 | 13 | 14250 | 19700 | 5400 | 6930 |

| 61819CE | 95 | 120 | 13 | 14475 | 20500 | 5000 | 6600 |

| 61820CE | 100 | 125 | 13 | 14700 | 21200 | 4800 | 6160 |

| 61821CE | 105 | 130 | 13 | 14925 | 21900 | 4800 | 6160 |

| 61822CE | 110 | 140 | 16 | 20475 | 29400 | 4300 | 5830 |

| 61824CE | 120 | 150 | 16 | 21225 | 31500 | 4000 | 5280 |

Why choose us:

Our company can according to the different needs of users, custom-make all ceramic bearings and hybrid ceramic bearings with ceramic balls of all precision levels, customized size range can be: inner diameter from 5 to 120mm, outer diameter from 10 to 200mm, including special non-standard size, special non-standard clearance, pairing and universal pairing angular contact high-speed, super high-speed bearings with ceramic ball and etc. Our company has our professional material recipe advantage, design and research and development ability, welcome your inquiry.

![]()

![]()

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews