-

Ceramic Ball Bearings

-

608 Ceramic Bearings

-

Hybrid Ceramic Bearings

-

Silicon Carbide Bearing

-

Ceramic Sliding Bearing

-

Ceramic Roller Bearings

-

Ceramic Thrust Bearing

-

Advanced Structural Ceramics

-

Silicon Nitride Ball

-

Silicon Carbide Ball

-

Zirconia Ceramic Ball

-

Silicon Carbide Ball Bearings

-

Silicon Nitride Ball Bearing

-

Zirconia Ceramic Bearing

-

Mechanical Sealing

-

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years.

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years. -

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

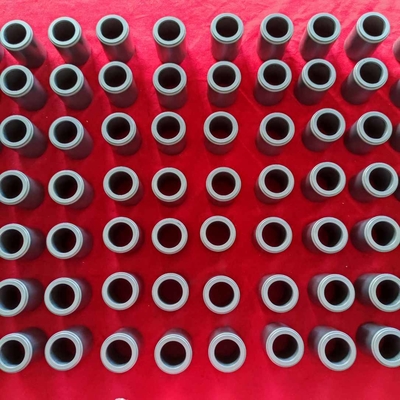

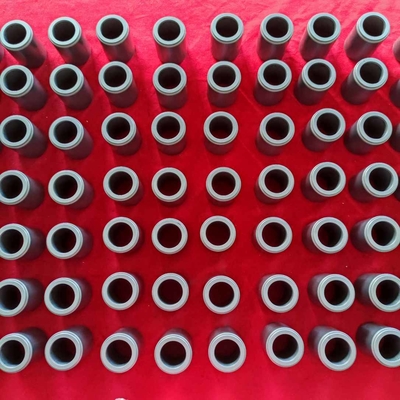

SSIC Sliding Bearing Sleeve High Temperature Tolerance

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Customized Ceramic Sliding Sleeve Bearing | Category | Ceramic Sliding Bearing |

|---|---|---|---|

| Material | Pressureless Sintered Silicon Carbide/Zirconia | Size | Customized,according To The Drawings |

| Application | Pumps | Package | Foam+carton Box |

| Quality | High Precision, Long Life, OEM Serive | Specification | Standard Size And Customized |

| Highlight | ceramic sliding bearing for marine environments,high temperature ceramic sliding bearing,chemical resistant ceramic sliding bearing |

||

Ceramic sliding bearings are advanced bearing technology constructed using premium ceramic materials including silicon nitride, silicon carbide, or zirconia. These materials provide superior performance compared to traditional steel bearings in demanding industrial applications.

- Corrosion Resistance: Excellent performance in harsh chemical and marine environments

- Reduced Friction: Smoother, harder surfaces minimize wear and extend component lifespan

- High Temperature Tolerance: Maintains structural integrity in extreme heat conditions

Ideal for aviation, aerospace, marine, petroleum, chemical processing, automotive, electronics, metallurgy, power generation, medical equipment, and defense applications.

| Property | Value |

|---|---|

| Maximum Temperature | 1650℃ |

| Density | 3.15-3.18 g/cm³ |

| Thermal Expansion | 4.0 (10-6/℃) |

| Thermal Conductivity | 120 W/m°K |

| Hardness | 2800 HV5 |

| Elastic Modulus | 410GPa |

| Chemical Stability | Superior resistance to acids, alkalis, and hydrofluoric acid |

- Superior high-temperature performance and stability

- Minimal clearance variation across temperature fluctuations

- Enhanced anti-bite and anti-stuck characteristics

- Self-lubricating for vacuum and difficult-to-lubricate applications

- Excellent resistance to chemical corrosion

- Electrical insulation and anti-static properties

- Non-magnetic for clean operation in magnetic environments

With three factories in China and advanced pressing, sintering, and processing equipment, we deliver high-quality ceramic bearing solutions. Our company (ZXSQ/CSQ) holds eleven invention patents and maintains a professional team dedicated to ceramic bearing innovation since 1982.

We specialize in both external and internal gear pump sliding bearings in silicon carbide material, with extensive experience supplying SSiC sliding bearings to international clients including Germany's Witte.

- Free samples available

- ISO standard compliance

- Inventory availability

- Small order acceptance

- OEM and custom bearing services

- Competitive pricing

A: We are a Beijing-based factory with over 40 years of ceramic bearing production experience, serving domestic and international clients.

A: We implement strict quality control including pre-production samples, precise inspections, and secure packaging to ensure product integrity.

A: Our portfolio includes ceramic deep groove ball bearings, angular contact bearings, hybrid bearings, linear bearings, and ceramic balls.

A: As an integrated manufacturer with three factories, we offer superior production capabilities, quality control, and delivery timelines.

A: We offer complete customization, sample confirmation, and comprehensive support throughout the product lifecycle.

We maintain strategic raw material partnerships to ensure consistent quality and pricing stability. Our customer-focused approach delivers value through quality products and exceptional service. Contact us today to discuss your ceramic bearing requirements.

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews