-

Ceramic Ball Bearings

-

608 Ceramic Bearings

-

Hybrid Ceramic Bearings

-

Silicon Carbide Bearing

-

Ceramic Sliding Bearing

-

Ceramic Roller Bearings

-

Ceramic Thrust Bearing

-

Advanced Structural Ceramics

-

Silicon Nitride Ball

-

Silicon Carbide Ball

-

Zirconia Ceramic Ball

-

Silicon Carbide Ball Bearings

-

Silicon Nitride Ball Bearing

-

Zirconia Ceramic Bearing

-

Mechanical Sealing

-

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years.

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years. -

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

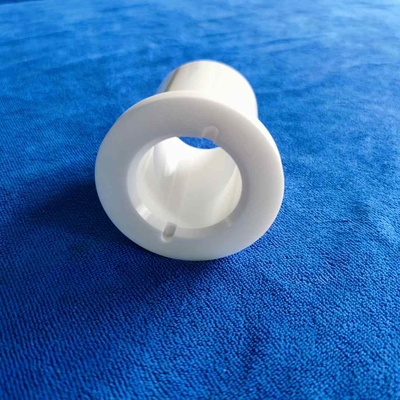

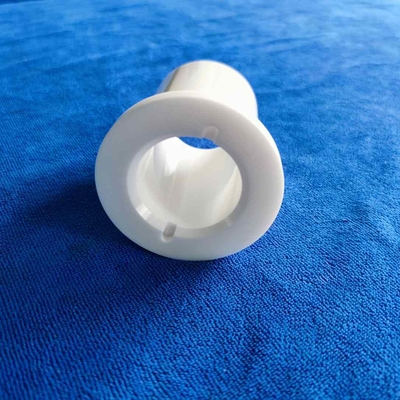

Custom ZrO2 Ceramic Step Sleeve Bearing for Pumps

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Customized Ceramic Sliding Bearing | Material | Ceramic SSIC Si3N4 Al2O3 ZrO2 |

|---|---|---|---|

| Category | Ceramic Sliding Bearing | Size | Customized, According To The Drawings |

| Use | A Variety Of Pumps | Pacage | Foam+cartom Box |

| Color | White | Durability | High |

| Corrosion Resistance | High | Friction | Low |

| Highlight | Custom ZrO2 ceramic bearing for pumps,Ceramic sliding sleeve bearing,Pump step sleeve bearing with warranty |

||

Customized ZrO2 Sliding Bearing Sleeve with Step

Product overview

The Zirconia Stepped Sleeve is a high-performance ceramic component made from Yttria-Stabilized Zirconia (YSZ), offering exceptional thermal resistance, corrosion resistance, high hardness, and low thermal conductivity. It is widely used in metallurgy, semiconductors, chemical processing, aerospace, and precision machinery, particularly in extreme environments requiring high-temperature insulation, wear resistance, and chemical inertness.

Key Features:

- Extreme Temperature Resistance (Up to 2200°C)

- Superior Thermal Shock Resistance

- High Chemical Inertness (Resistant to acids, alkalis, and molten metals)

- High Hardness & Wear Resistance (Vickers Hardness ≥1200 HV)

- Low Thermal Conductivity (Excellent Insulation Performance)

- Precision Machining (High dimensional accuracy for demanding applications)

Technical Specifications

| Parameter | Value |

| Material | Yttria-Stabilized ZrO₂ (YSZ) |

| Density | 6.04 g/cm³ |

| Hardness | 1300 HV |

| Max. Temp. | 2200°C |

| CTE | 10.3×10⁻⁶/K (RT-1000°C) |

| Flexural Strength | 900 MPa |

Typical Applications

- High-Temperature Furnaces & Melting Equipment (Crucibles, Thermocouple Protection Tubes)

- Semiconductor Manufacturing (Wafer Processing, CVD Reactor Components)

- Chemical Corrosion-Resistant Parts (Pump Bushings, Valve Seals)

- Aerospace (Thermal Insulation Components, Jet Engine Parts)

- Precision Machinery (High-Precision Bearing Sleeves, Wear-Resistant Guides)

![]()

![]()

Why choose us:

Our factory and processing machine:

We have three factories in China, can meet the needs for different custmers, and also we have advanced pressing, sintering and processing machines.

According to the structure difference, it can be divided into: external gear pump and internal gear pump. Our company has ample production experience of both kind of the gear pump sliding bearing in material of silicon carbide. We did supply these SSiC sliding bearing for Germany Witte for many years.

Our bearing advantage:

1. Free sample bearing

2. ISO standard

3. In stock bearing

4. Bearing small order accepted

5. OEM bearing service

6. Customized bearing, Customer’s bearing drawing or samples accepted

7. Competitive factory price bearing

![]()

![]()

![]()

FQA

- Q:Who are we?

- A:We are a factory in Beijing, China. We have been producing and selling ceramic bearings for more than 40 years. We have established friendly cooperative relations with many domestic and foreign companies.

- Q:How can we guarantee quality?

- A:We always produce samples before mass production, and produce in strict accordance with customer requirements and production regulations. After the completion of production, we will use inspection equipment to carry out precise inspection of products, and our packaging adopts the double insurance of foam and carton, to strictly ensure the quality of products.

- Q:What can you buy from us?

- A:Ceramic deep groove ball bearings, ceramic angular contact ball bearings, hybrid ceramic ball bearings, ceramic linear bearings, etc and all kinds of ceramic balls.

- Q:Why should you buy from us not from other suppliers?

- A:We are an industry and trade integrated company, we have three factories, with today's production and inspection equipment, can provide better delivery dates and product quality.

- Q:What service can we provide?

- A:We will provide high quality products and customized services, which can be fully customized according to user needs. We can provide samples for customer's confirmation.

Welcome your enquiry

- We supply bearings, high quality products, if you need to buy or consult the price of bearings, please contact us. We are a set of bearing research and development, production, sales, service in one of the professional bearing company, providing bearing products and related technical services. We choose high quality raw materials, carefully do each set of bearings.

- We adhere to customer demand as the guidance, and strive to provide customers with quality products and after-sales service, create value for customers, do customers partner. Welcome to discuss the cooperation!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews