-

Ceramic Ball Bearings

-

608 Ceramic Bearings

-

Hybrid Ceramic Bearings

-

Ceramic Roller Bearings

-

Ceramic Thrust Bearing

-

Ceramic Sliding Bearing

-

Advanced Structural Ceramics

-

Silicon Nitride Ball

-

Silicon Carbide Ball

-

Zirconia Ceramic Ball

-

Silicon Carbide Ball Bearings

-

Silicon Nitride Ball Bearing

-

Zirconia Ceramic Bearing

-

Mechanical Sealing

-

Silicon Carbide Bearing

-

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years.

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years. -

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

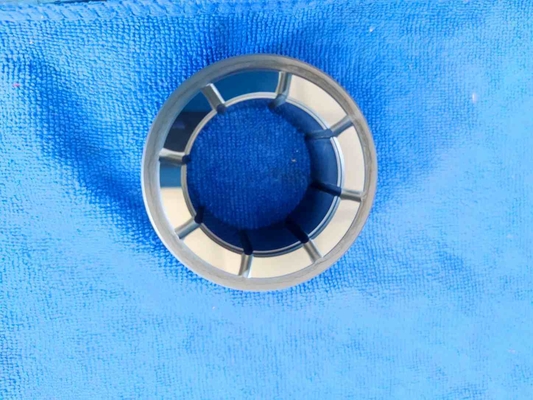

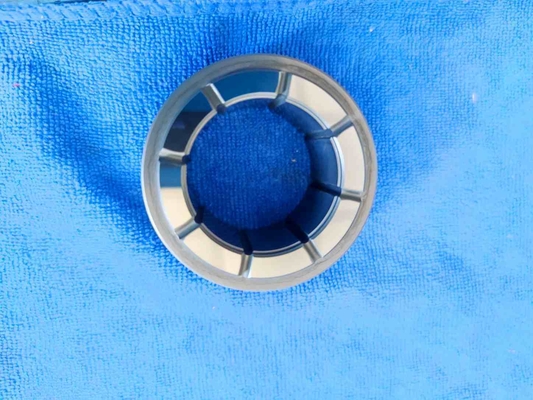

Customized SiCC+C Bushing Meeting High Temperature Demands Of Industrial Automotive

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Customized Ceramic Sliding Sleeve Bearing | Category | Ceramic Sliding Bearing |

|---|---|---|---|

| Material | Pressureless Sintered Silicon Carbide | Size | Customized,according To The Drawings |

| Application | Pumps | Package | Foam+carton Box |

| Quality | High Precision, Long Life, OEM Serive | Specification | Standard Size And Customized |

| Highlight | High Temperature SiCC+C Bushing,SiCC+C Bushing Customized,Automotive SiCC+C Bushing |

||

Silicon Carbide-Graphite Composite Bushing Product Introduction

Designed for stainless steel magnetic drive pumps, the SiC+Graphite composite bushing combines high-hardness silicon carbide with self-lubricating graphite, delivering both wear resistance and self-lubrication – a core component for leak-free pump operation.

Key Features

| Feature | Technical Advantage |

| Dual-Phase Structure | SiC matrix (90%) for hardness + graphite phase (10%) for self-lubrication |

| Corrosion Resistance | Withstands pH 0-14 media (HCl, HF, etc.) |

| Dry-Run Capability | Survives ≤30s dry-running with stable μ=0.08-0.12 |

| Thermal Stability | Operates at -40°C ~ 250°C (graphite oxidation limit) |

Technical Specifications

| Parameter | Value |

| Density | 2.9-3.0 g/cm³ |

| Hardness | 2200 HV |

| Porosity | ≤5% |

| Thermal Conductivity | 85 W/m·K |

| Max PV | 3.5 MPa·m/s |

Design for Magnetic Pumps

- Precision clearance: 0.03-0.05mm ID/shaft gap (prevents fluid flashing)

- Anti-rotation grooves: Outer spiral channels improve coolant flow

- Fail-safe: SiC matrix provides backup support after graphite wear

Applications

- Chemical mag pumps: 31% HCl transfer, >20,000h service life

- Electroplating pumps: CrO₃ resistance, zero metal contamination

- Pharmaceutical pumps: FDA-compliant for WFI systems

Why choose us

Our factory and processing machine:

We have three factories in China, can meet the needs for different custmers, and also we have advanced pressing, sintering and processing machines.

Our company logo is ZXSQ and CSQ, and possesses eleven invention patents for utility models. The company now has a high-quality professional team consisting of dozens of members, to provide you with high-quality and perfect service, according to customer requirements to order a variety of bearing products.

Since the year of 1982 we have accumulated abundant experience in the production over the past more than 40 years, devoting ourselves whole -heartedly to the research and development of ceramic bearing material, our processing technique and improvement of our equipments.

Having undergone several evolution and transformation, our company has now become the leading enterprise in China domestic market in the fields of ceramic bearing and ceramic material products.

According to the structure difference, it can be divided into: external gear pump and internal gear pump. Our company has ample production experience of both kind of the gear pump sliding bearing in material of silicon carbide. We did supply these SSiC sliding bearing for Germany Witte for many years.

Our Bearing Advantage:

1. Free Sample bearing

2. ISO Standard

3. In Stock bearing

4. Bearing Small order accepted

5. OEM bearing service

6. Customized bearing, Customer’s bearing drawing or samples accepted

7. Competitive factory price bearing

FQA

Q:Who are we?

A:We are a factory in Beijing, China. We have been producing and selling ceramic bearings for more than 40 years. We have established friendly cooperative relations with many domestic and foreign companies.

Q:How can we guarantee quality?

A:We always produce samples before mass production, and produce in strict accordance with customer requirements and production regulations. After the completion of production, we will use inspection equipment to carry out precise inspection of products, and our packaging adopts the double insurance of foam and carton, to strictly ensure the quality of products.

Q:What can you buy from us?

A:Ceramic deep groove ball bearings, ceramic angular contact ball bearings, hybrid ceramic ball bearings, ceramic linear bearings, etc and all kinds of ceramic balls.

Q:Why should you buy from us not from other suppliers?

A:We are an industry and trade integrated company, we have three factories, with today's production and inspection equipment, can provide better delivery dates and product quality.

Q:What service can we provide?

A:We will provide high quality products and customized services, which can be fully customized according to user needs. We can provide samples for customer's confirmation.

Welcome your enquiry

We cooperate with raw material suppliers to ensure product quality and profit stability without being affected by international raw material price fluctuations. It is not suppressed by foreign enterprises by raising the price of raw materials. At the same time with raw material production technology, when necessary, we can produce raw materials by ourselves.

We adhere to customer demand as the guidance, and strive to provide customers with quality products and after-sales service, create value for customers, do customers partner. Welcome to discuss the cooperation!