-

Ceramic Ball Bearings

-

608 Ceramic Bearings

-

Hybrid Ceramic Bearings

-

Silicon Carbide Bearing

-

Ceramic Sliding Bearing

-

Ceramic Roller Bearings

-

Ceramic Thrust Bearing

-

Advanced Structural Ceramics

-

Silicon Nitride Ball

-

Silicon Carbide Ball

-

Zirconia Ceramic Ball

-

Silicon Carbide Ball Bearings

-

Silicon Nitride Ball Bearing

-

Zirconia Ceramic Bearing

-

Mechanical Sealing

-

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years.

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years. -

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

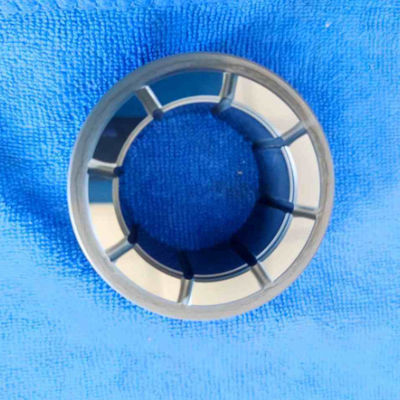

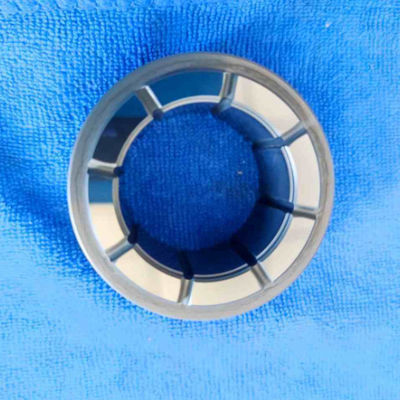

Customized Pressureless Sintered SSIC Bushing for Pumps

| Name | Customized Ceramic Sliding Sleeve Bearing | Category | Ceramic Sliding Bearing |

|---|---|---|---|

| Material | Pressureless Sintered Silicon Carbide | Size | Customized,according To The Drawings |

| Application | Pumps | Package | Foam+carton Box |

| Quality | High Precision, Long Life, OEM Serive | Specification | Standard Size And Customized |

| Highlight | High Temperature SiCC+C Bushing,SiCC+C Bushing Customized,Automotive SiCC+C Bushing |

||

Designed for stainless steel magnetic drive pumps, the SiC+Graphite composite bushing combines high-hardness silicon carbide with self-lubricating graphite, delivering both wear resistance and self-lubrication - a core component for leak-free pump operation.

| Feature | Technical Advantage |

|---|---|

| Dual-Phase Structure | SiC matrix (90%) for hardness + graphite phase (10%) for self-lubrication |

| Corrosion Resistance | Withstands pH 0-14 media (HCl, HF, etc.) |

| Dry-Run Capability | Survives ≤30s dry-running with stable μ=0.08-0.12 |

| Thermal Stability | Operates at -40°C ~ 250°C (graphite oxidation limit) |

| Parameter | Value |

|---|---|

| Density | 2.9-3.0 g/cm³ |

| Hardness | 2200 HV |

| Porosity | ≤5% |

| Thermal Conductivity | 85 W/m*K |

| Max PV | 3.5 MPa*m/s |

- Precision clearance: 0.03-0.05mm ID/shaft gap (prevents fluid flashing)

- Anti-rotation grooves: Outer spiral channels improve coolant flow

- Fail-safe: SiC matrix provides backup support after graphite wear

- Chemical mag pumps: 31% HCl transfer, >20,000h service life

- Electroplating pumps: CrO₃ resistance, zero metal contamination

- Pharmaceutical pumps: FDA-compliant for WFI systems

We have three factories in China to meet different customer needs, equipped with advanced pressing, sintering and processing machines.

Our company logos are ZXSQ and CSQ, and we possess eleven invention patents for utility models. With a high-quality professional team of dozens of members, we provide customized bearing products according to customer requirements.

Since 1982, we have accumulated over 40 years of production experience, dedicated to ceramic bearing material research and development, processing technique improvement, and equipment upgrades. Through continuous evolution, we have become a leading enterprise in China's ceramic bearing and ceramic material products market.

We have extensive production experience with both external and internal gear pump sliding bearings in silicon carbide material, having supplied SSiC sliding bearings to Germany's Witte for many years.

- Free Sample bearing

- ISO Standard

- In Stock bearing

- Bearing Small order accepted

- OEM bearing service

- Customized bearing, Customer's bearing drawing or samples accepted

- Competitive factory price bearing

A: We are a factory in Beijing, China with over 40 years of experience producing ceramic bearings. We have established cooperative relations with many domestic and international companies.

A: We produce samples before mass production and strictly follow customer requirements. Products undergo precise inspection using specialized equipment, with double packaging protection (foam and carton) to ensure quality.

A: Ceramic deep groove ball bearings, ceramic angular contact ball bearings, hybrid ceramic ball bearings, ceramic linear bearings, and various ceramic balls.

A: As an industry and trade integrated company with three factories and modern production/inspection equipment, we offer better delivery times and product quality.

A: We provide high quality products and fully customized services according to user needs, including sample confirmation.

We cooperate with raw material suppliers to ensure stable product quality and pricing, unaffected by international raw material fluctuations. When necessary, we can produce raw materials ourselves.

Customer demand drives our operations as we strive to provide quality products and after-sales service, creating value as your trusted partner. We welcome discussion of potential cooperation!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews