-

Ceramic Ball Bearings

-

608 Ceramic Bearings

-

Hybrid Ceramic Bearings

-

Silicon Carbide Bearing

-

Ceramic Sliding Bearing

-

Ceramic Roller Bearings

-

Ceramic Thrust Bearing

-

Advanced Structural Ceramics

-

Silicon Nitride Ball

-

Silicon Carbide Ball

-

Zirconia Ceramic Ball

-

Silicon Carbide Ball Bearings

-

Silicon Nitride Ball Bearing

-

Zirconia Ceramic Bearing

-

Mechanical Sealing

-

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years.

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years. -

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

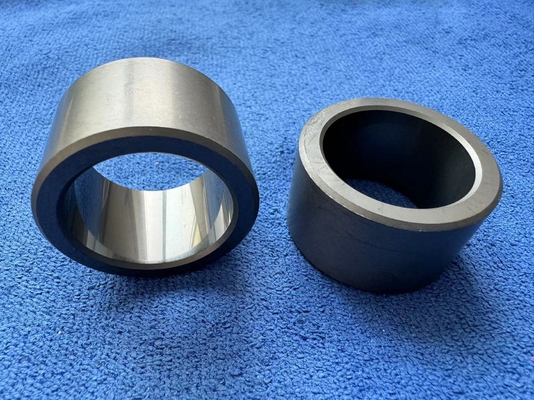

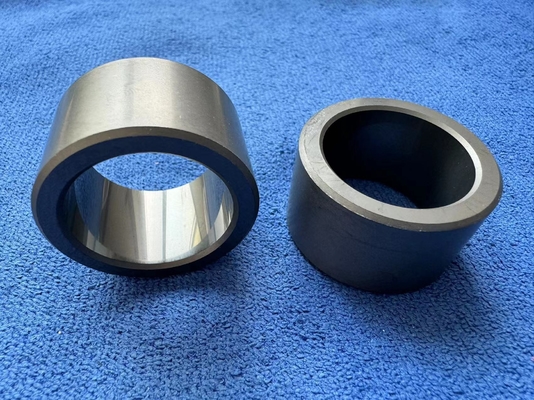

Ceramic Sliding Bush Bearing With Low Maintenance And Extended Lifespan

| Place of Origin | China |

|---|---|

| Brand Name | Ceramic Sliding Bearing |

| Certification | FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001 |

| Model Number | Customized Products |

| Minimum Order Quantity | 20-50pcs |

| Price | Negotiable |

| Packaging Details | Foam+carton |

| Delivery Time | 30-45 works day |

| Payment Terms | T/T |

| Supply Ability | 2000pcs per month |

| Corrosion Resistance | High | Load Capacity | High |

|---|---|---|---|

| Application | Machinery | Speed | High |

| Pressure | High | Friction | Low |

| Maintenance | Low | Lifespan | Long |

| Highlight | Extended Lifespan Ceramic Sliding Bush Bearing,Low Maintenance Ceramic Sliding Bush Bearing,Low Maintenance Sliding Bush Bearing |

||

Product Description:

The Ceramic Sliding Bearing is made of SSIC (sintered silicon carbide), a high-performance ceramic material that offers superior wear resistance, excellent corrosion resistance, and high-temperature stability. SSIC has a high modulus of elasticity, which enables it to withstand high stress and pressure without deforming or cracking.

The Ceramic Sliding Bearing is ideal for use in machinery applications that require high-speed and high-pressure operation such as pumps, compressors, and turbines. Its unique structure and SSIC material allow for reduced friction, lower maintenance costs, and longer service life.

The SSIC ceramic material used in this sliding bearing has a high thermal conductivity that promotes efficient heat dissipation, minimizing the risk of overheating and thermal damage. Additionally, the material's high chemical stability makes it resistant to corrosion from harsh chemicals or abrasive materials that can cause wear and tear on other types of bearings.

Overall, the Ceramic Sliding Bearing is a reliable and high-performance option for machinery applications that require a durable and long-lasting solution. Its unique structure and SSIC ceramic material offer exceptional wear and corrosion resistance, high-temperature stability, and efficient operation even under high-pressure and high-speed conditions.

Features:

- Product Name: Ceramic Sliding Bearing

- Durability: High

- Corrosion Resistance: High

- Lifespan: Long

- Structure: Sliding Bearing

- Application: Machinery

- Customized: Yes

- Material: SSIC (Silicon Carbide Ceramic)

Technical Parameters:

| Size | Customized |

| Noise | Low |

| Maintenance | Low |

| Durability | High |

| Pressure | High |

| Material | Ceramic (SSIC - Silicon Carbide) |

| Load Capacity | High |

| Speed | High |

| Structure | Sliding Bearing |

| Temperature | High |

| Additional Information | According to the drawing |

Applications:

With a minimum order quantity of 20-50pcs, the Ceramic Sliding Bearing is affordable and negotiable in price. The product is packaged in foam and cartons, making it easy to handle and transport. Delivery takes between 30-45 working days, and payment terms are flexible, allowing clients to pay via T/T. The product has a supply ability of 2000pcs per month, ensuring that clients' demands are met.

The Ceramic Sliding Bearing is low maintenance, durable, and has a long lifespan. Its low friction makes it ideal for use in machinery, reducing wear and tear and increasing efficiency. The product is made of Silicon Carbide (SSIC), and according to the drawing.

The Ceramic Sliding Bearing is suitable for various application occasions and scenarios, including:

- Manufacturing Plants: The product can be used in various manufacturing plants, including automotive, aerospace, and defense, among others.

- Power Plants: The Ceramic Sliding Bearing is ideal for use in power plants, including hydroelectric, thermal, and nuclear power plants.

- Food Processing Plants: The product meets various international standards, including FDA certification, making it ideal for use in food processing plants.

- Oil and Gas Industry: The Ceramic Sliding Bearing is suitable for use in the oil and gas industry, where it can withstand harsh environmental conditions, including high temperatures and pressures.

- Marine Industry: The product is corrosion-resistant, making it ideal for use in the marine industry, including shipbuilding and offshore oil rigs.

In conclusion, the Ceramic Sliding Bearing is a high-quality product suitable for various machinery. Its durability, low maintenance, and long lifespan make it an ideal product for clients looking for a long-term solution to their machinery needs. Its low friction ensures that machinery runs smoothly, reducing wear and tear and increasing efficiency. With its affordable price, flexible payment terms, and supply ability of 2000pcs per month, clients can be assured of timely delivery and quality products.

Customization:

- Brand Name: Ceramic Sliding Bearing

- Model Number: Customized Products

- Place of Origin: China

- Certification: FDA, REACH, ROHS, ISO9001, ISO14001, ISO45001

- Minimum Order Quantity: 20-50pcs

- Price: Negotiable

- Packaging Details: Foam+carton

- Delivery Time: 30-45 works day

- Payment Terms: T/T

- Supply Ability: 2000pcs per month

- Noise: Low

- Lifespan: Long

- Size: According to the drawing, Customized

- Friction: Low

- Material: Ceramic

Support and Services:

Our Ceramic Sliding Bearing product comes with a comprehensive technical support and services package to ensure optimal performance and longevity. Our team of experienced and knowledgeable engineers are available to provide installation and maintenance assistance, as well as troubleshooting support should any issues arise. Additionally, we offer customization options to meet specific application requirements. Our product technical support and services aim to provide our customers with complete peace of mind and satisfaction.

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews