-

Ceramic Ball Bearings

-

608 Ceramic Bearings

-

Hybrid Ceramic Bearings

-

Silicon Carbide Bearing

-

Ceramic Sliding Bearing

-

Ceramic Roller Bearings

-

Ceramic Thrust Bearing

-

Advanced Structural Ceramics

-

Silicon Nitride Ball

-

Silicon Carbide Ball

-

Zirconia Ceramic Ball

-

Silicon Carbide Ball Bearings

-

Silicon Nitride Ball Bearing

-

Zirconia Ceramic Bearing

-

Mechanical Sealing

-

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years.

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years. -

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

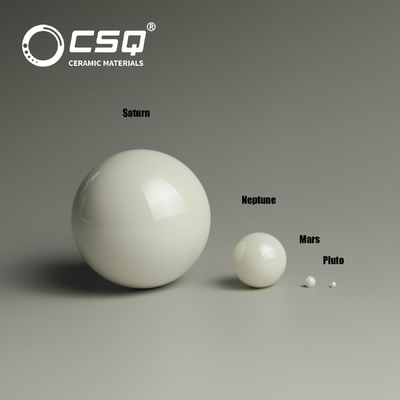

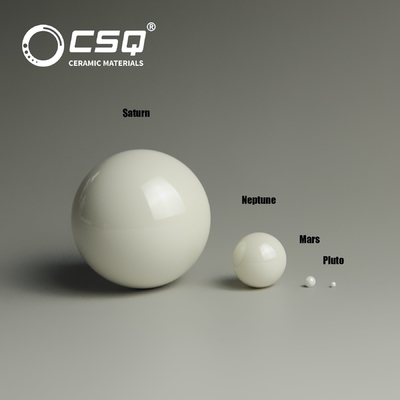

3.75mm - 50mm Zirconia Ceramic Balls For Chemical / Automotive / Food Industry

| Place of Origin | China |

|---|---|

| Brand Name | CSQ |

| Certification | FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001 |

| Minimum Order Quantity | 20-50 PCS (negotiable) |

| Price | Negotiable |

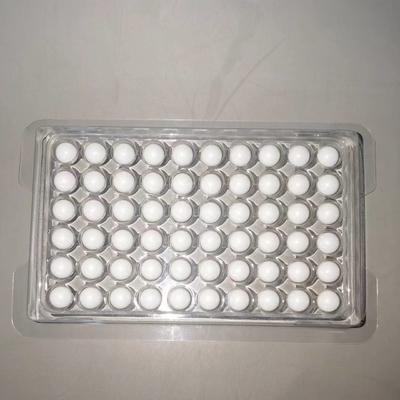

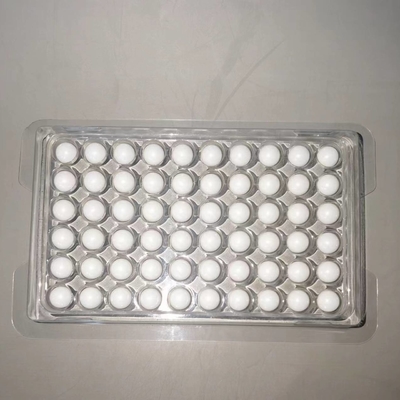

| Packaging Details | Foam+carton box |

| Delivery Time | In Stock: 3-7 work days; No Stock: 20-45 work days |

| Payment Terms | T/T or Paypal |

| Supply Ability | 20,000 pcs per month |

| Name | Zirconia Ceramic Ball | Category | Zirconia Ceramic Ball |

|---|---|---|---|

| Size | 3.75mm-50mm | Material | Zirconia (zro2) |

| Key Words | Wear-resistance, Corrosion-resistance, Longer Life | Grade | G3/G5/G10 |

| Technology | HIP (High Temperature Insostatic Pressing) | Application | Food/Chemical/Automotive Industry |

| Highlight | 3.75mm zirconia ceramic balls,food industry zirconia ceramic balls,50mm zirconia balls |

||

Description of Zirconia Ceramic Balls

Zirconia ceramic balls are a type of ceramic ball made from zirconium dioxide (ZrO2) material. They are known for their high strength, hardness, wear resistance, and chemical stability. Zirconia ceramic balls have a very fine microstructure, which gives them excellent mechanical properties.

Zirconia ceramic balls are commonly used in industrial applications that require high wear resistance, such as grinding media for milling and dispersion processes in the pharmaceutical, mining, and paint industries. They are also used in high-temperature applications, such as furnace tubes and thermocouple protection tubes.

Overall, zirconia ceramic balls are a high-performance material with a wide range of industrial applications.

| Parameter | Value |

| Name | Zirconia Ceramic ball |

| Chemical Composition | ZrO2 (typically >94%) |

| Color | White |

| Density | 5.95-6.05 g/cm3 |

| Hardness | 1200-1500HV |

| Flexural Strength | 800-1000 Mpa |

| Young's Modulus | 200-250 GPa |

| Coefficient of thermal expansion | 9-10 x 10^-6/K |

| Thermal Conductivity | 2-3 W/mK |

| Maximum Operating Temperature | >1000% |

| Grade | G3/G5/G10 |

![]()

![]()

Application of Zirconia Ceramic Balls

►Food Industry

![]()

Hygienic: Ceramic balls are non-porous, which means they do not absorb liquids, oils, or food particles. This makes them easier to clean and sanitize, reducing the risk of contamination and ensuring food safety.

High-temperature resistance: Ceramic balls can withstand high temperatures, making them suitable for use in ovens, deep fryers, and other high-temperature food processing equipment.

Overall, the use of ceramic balls in the food industry can improve food safety, reduce maintenance costs, and also can enhance product quality.

►Chemical Industry

![]()

Chemical resistance: Ceramic balls are highly resistant to chemicals and acids, making them suitable for use in corrosive chemical processing applications.

High-purity: Ceramic balls have high-purity levels, making them suitable for use in chemical processing applications where contamination is a concern.

Non-reactive: Ceramic balls are inert and do not react with drugs or chemicals, which means they do not affect the purity or potency of the drug. This makes them ideal for use in drug processing and packaging applications where drug quality is critical.

Overall, the use of ceramic balls in the chemical industry can improve chemical purity, reduce maintenance costs, and enhance product quality and safety.

About our company-ZXSQ

►Certification

![]()

►Production lines and inspection equipments

![]()

We have three factories in China, can meet the needs for different customers, and also we have advanced pressing, sintering and processing machines. Our company has specialized production of high-precision ceramic ball production line, as well as ceramic bearing grinder, automatic assembly production line. In addition, our HIP sintering furnace from Sweden ABB company, so we are confident that you will be satisfied with our products.

Technical Support and Service

We are providing the highest level of product support and service. Our experienced team of professionals are dedicated to addressing your inquiries quickly and accurately.

We provide technical support and services for 6000 ceramic ball bearings products, including:

•Product troubleshooting and repair

•Product customization and optimization

•Product upgrades and updates

We also provide support for warranty claims and product returns. If you have any questions or need any assistance, please feel free to contact us.

FAQ

1. Q:What the MQQ of your company?

A:MQQ is 20-50 pcs.

2. Q:Could you accept OEM and customize?

A:YES,we can customize according to your sample or drawing.

3. Q:Could you supply sample for free?

A:Yes,we can supply sample for free, but not charge the freight.

4. Q:Does your factory have any certificate?

A:yes.we have FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001.

5. Q:IS you company factory or Trade Company?

A:We are the supplier and we have our own factory.

6. Q:Could you tell me the material of our bearing?

A:We have ZrO2(Zirconia), Silicon Carbide(SSiC), Silicon Nitride(Si3N4), Aluminia(Al2O3).

7. Q:Could you offer door to door service?

A:Yes,by express(DHL,FEDEX,TNT,UPS.)

8. Q:Could you tell me the payment term of your company can accept?

A:T/T.

9. Q:Your factory how to control the quality?

A: All bearing parts before the production and the production process, strict inspection by 100%, including crack detection, roundness, hardness, roughness, and the geometry size, all bearing meet ISO international standard.

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews