-

Ceramic Ball Bearings

-

608 Ceramic Bearings

-

Hybrid Ceramic Bearings

-

Silicon Carbide Bearing

-

Ceramic Sliding Bearing

-

Ceramic Roller Bearings

-

Ceramic Thrust Bearing

-

Advanced Structural Ceramics

-

Silicon Nitride Ball

-

Silicon Carbide Ball

-

Zirconia Ceramic Ball

-

Silicon Carbide Ball Bearings

-

Silicon Nitride Ball Bearing

-

Zirconia Ceramic Bearing

-

Mechanical Sealing

-

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years.

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years. -

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

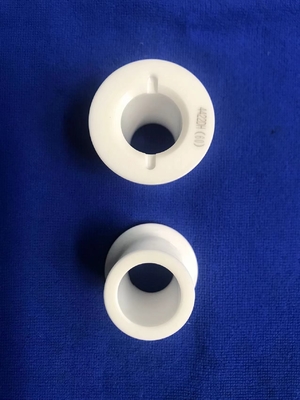

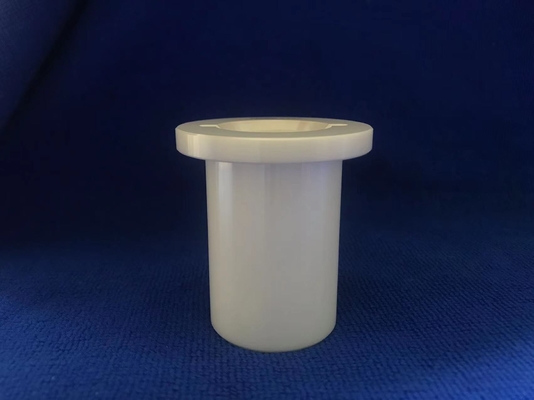

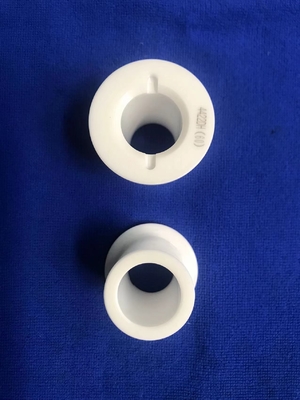

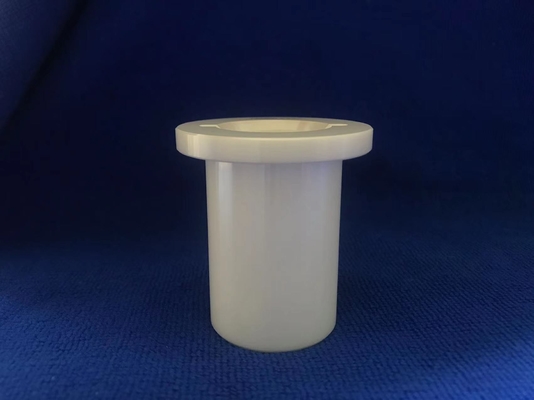

Pumps Ssic Ceramic Sliding Zro2 Bearing Corrosion Resistance High Strength And Toughness

| Name | Customized Ceramic Sliding Bearing | Category | Ceramic Sliding Bearing |

|---|---|---|---|

| Material | Ceramic SSIC Si3N4 Al2O3 ZrO2 | Size | Customized, According To The Drawings |

| Use | A Variety Of Pumps | Pacage | Foam+cartom Box |

| Highlight | high strength zro2 bearing,corrosion resistance zro2 bearing,ssic ceramic sliding bearing |

||

Customized ZrO2 Sliding Bearing For Submerged Pump or Magnetic Drive Pump or Canned Motor Pump

Description of Customized ceramic sliding bearing:

Sliding bearing is a crucial transmission part, as the support and rotary unit of canned motor pump. With the excellent corrosion resistance, wear resistance and other properties, Zirconia (ZrO2) is one of the best sliding bearing material for the pumps.

The ZrO2 sliding bearing is taken as standard part in submerged pump and used by many submerged pumps in domestic or foreign enterprises. Our company has our design and recipe advantage of the sliding bearing in material of pressureless sintered silicon carbide and are stably suppling the parts for many famous pump enterprise in Europe and Japen for many years.

| ►Key properties of pressureless sintered silicon carbide |

| ♦ Max Temperature up to 1650℃ |

| ♦ Low density:3.15-3.18 g/cm3 |

| ♦ High strength |

| ♦ Low thermal expansion : 4.0 (10-6/℃) |

| ♦ High thermal conductivity:120 W/m°K |

| ♦ High hardness:2800 HV5 |

| ♦ High elastic modulus: 410GPa |

| ♦ Superior chemical stability,resistance to acid and alkali corrosion (incld. hydrofluoric acid) |

Characteristic:

ZrO2 ceramic sliding bearings are made from a type of ceramic material called zirconia, which has several unique characteristics that make it ideal for certain applications. Some of the key characteristics of zirconia ceramic sliding bearings include:

High strength and toughness: Zirconia is a very strong and tough material, which means that it can resist cracking and breaking even under high stress or impact.

Wear resistance: Zirconia has excellent wear resistance, which makes it ideal for use in applications where components are subjected to high levels of friction or abrasion.

Low thermal conductivity: Zirconia has a low thermal conductivity, which means that it does not conduct heat very well. This can be an advantage in certain applications, such as in the production of high-precision machinery where thermal expansion and contraction need to be tightly controlled.

Chemical resistance: Zirconia is highly resistant to chemical attack, which makes it ideal for use in harsh environments where components may be exposed to corrosive substances.

Biocompatibility: Zirconia is biocompatible, which means that it is well-suited to medical and dental applications where it may come into contact with the human body.

Overall, zirconia ceramic sliding bearings are valued for their combination of strength, toughness, wear resistance, and other unique characteristics, which make them ideal for use in a variety of high-precision applications.

![]()

Application:

Ceramic sliding bearings are typically used in the manufacturing or production of precision machinery, particularly in the semiconductor industry. They are used as part of the assembly process to ensure precise alignment and spacing between components.

Some specific uses of zirconia ceramic sliding bearing include:

Wire bonding: Zirconia ceramic sliding bearing can be used as guides for the bonding wires that connect various components in microelectronics. They help to ensure that the wires are precisely aligned and spaced, which is important for the functionality and reliability of the device.

Optical fiber alignment: Zirconia ceramic sliding bearing can be used to align and hold optical fibers in place during the manufacturing of optical components such as lasers, amplifiers, and detectors.

Precision machining: Zirconia ceramic sliding bearing can be used as spacers or guides in precision machining applications, such as in the production of micro gears, bearings, and other small parts.

Overall, zirconia ceramic sliding bearing are valued for their high strength, hardness, and wear resistance, which make them ideal for use in high-precision applications where accuracy and durability are critical.

Our factory and processing machine:

We have three factories in China, can meet the needs for different custmers, and also we have advanced pressing, sintering and processing machines.

Why choose us:

According to the structure difference, it can be divided into: external gear pump and internal gear pump. Our company has ample production experience of both kind of the gear pump sliding bearing in material of silicon carbide. We did supply these SSiC sliding bearing for Germany Witte for many years.

Our bearing advantage:

1. Free sample bearing

2. ISO standard

3. In stock bearing

4. Bearing small order accepted

5. OEM bearing service

6. Customized bearing, Customer’s bearing drawing or samples accepted

7. Competitive factory price bearing

![]()

![]()

![]()

FQA

Q:Who are we?

A:We are a factory in Beijing, China. We have been producing and selling ceramic bearings for more than 40 years. We have established friendly cooperative relations with many domestic and foreign companies.

Q:How can we guarantee quality?

A:We always produce samples before mass production, and produce in strict accordance with customer requirements and production regulations. After the completion of production, we will use inspection equipment to carry out precise inspection of products, and our packaging adopts the double insurance of foam and carton, to strictly ensure the quality of products.

Q:What can you buy from us?

A:Ceramic deep groove ball bearings, ceramic angular contact ball bearings, hybrid ceramic ball bearings, ceramic linear bearings, etc and all kinds of ceramic balls.

Q:Why should you buy from us not from other suppliers?

A:We are an industry and trade integrated company, we have three factories, with today's production and inspection equipment, can provide better delivery dates and product quality.

Q:What service can we provide?

A:We will provide high quality products and customized services, which can be fully customized according to user needs. We can provide samples for customer's confirmation.

Welcome your enquiry

We supply bearings, high quality products, if you need to buy or consult the price of bearings, please contact us. We are a set of bearing research and development, production, sales, service in one of the professional bearing company, providing bearing products and related technical services. We choose high quality raw materials, carefully do each set of bearings.

We adhere to customer demand as the guidance, and strive to provide customers with quality products and after-sales service, create value for customers, do customers partner. Welcome to discuss the cooperation!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews