-

Ceramic Ball Bearings

-

608 Ceramic Bearings

-

Hybrid Ceramic Bearings

-

Silicon Carbide Bearing

-

Ceramic Sliding Bearing

-

Ceramic Roller Bearings

-

Ceramic Thrust Bearing

-

Advanced Structural Ceramics

-

Silicon Nitride Ball

-

Silicon Carbide Ball

-

Zirconia Ceramic Ball

-

Silicon Carbide Ball Bearings

-

Silicon Nitride Ball Bearing

-

Zirconia Ceramic Bearing

-

Mechanical Sealing

-

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years.

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years. -

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

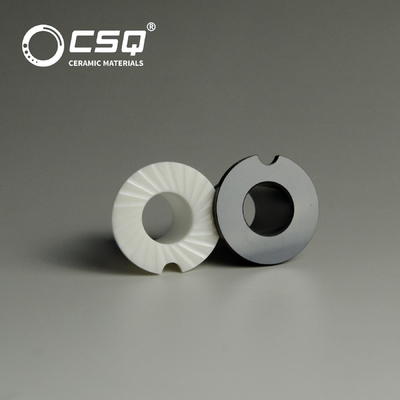

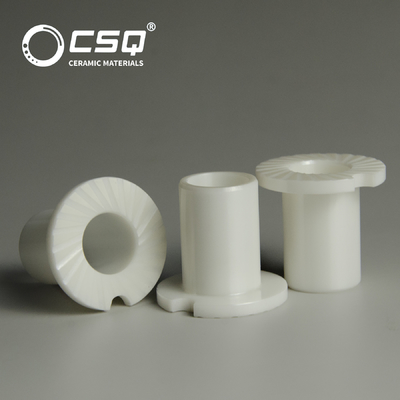

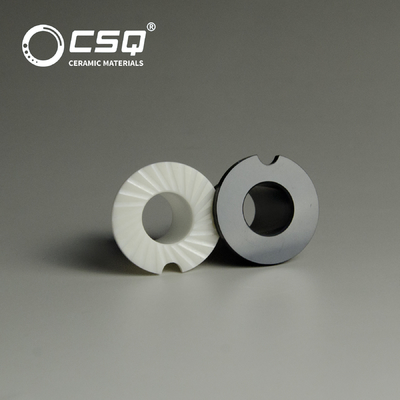

Black Industrial Ceramic Bearings Step Sleeve ZrO2 SSiC

| Name | Customized Ceramic Step Sleeve | Category | Ceramic Sliding Bearing |

|---|---|---|---|

| Material | SSiC (Silicon Carbide) Or ZrO2 (Zirconia) | Size | Customized, According To The Drawings |

| Precision | Customized, According To The Drawings | MOQ | 20 Pieces |

| Pacage | Foam+cartom Box | Delivery Time | 40-50 Work Days |

| Highlight | black ceramic bearings CSQ,Ceramic Step Sleeve ZrO2 CSQ,Ceramic Step Sleeve SSiC CSQ |

||

Customized Ceramic Step Sleeve In Material Of SSiC Or ZrO2

Description of ceramic step sleeve:

Because of the excellent properties of silicon carbide and zirconia material, especially their good chemical stability and corrosion resistance, they are widely used in the industries with special working condition. Our company had stably supplied ceramic step sleeves for European pump companies, like Germany DST and Germany DRE for many years, so we have abundant experiences in production of ceramic step sleeves. Welcome your inquiry.

| ►Key properties of pressureless sintered silicon carbide |

| ♦ Max Temperature up to 1650℃ |

| ♦ Low density:3.15-3.18 g/cm3 |

| ♦ High strength |

| ♦ Low thermal expansion : 4.0 (10-6/℃) |

| ♦ High thermal conductivity:120 W/m°K |

| ♦ High hardness:2800 HV5 |

| ♦ High elastic modulus: 410GPa |

| ♦ Superior chemical stability,resistance to acid and alkali corrosion (incld. hydrofluoric acid) |

| ►Key properties of zirconia |

| ♦ Max Temperature up to 380℃ |

| ♦ High density: 6.09 g/cm3 |

| ♦ Low thermal conductivity |

| ♦ Chemical stability, resistance to acid and alkali corrosion |

| ♦ High fracture toughness KIC:8-11 MPa-m1/2 |

| ♦ Good electric insulation |

| ♦ Better bearing capacity |

| ♦ Wear resistance |

| ♦ High hardness : 1300 HV5 |

![]()

![]()

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews