-

Ceramic Ball Bearings

-

608 Ceramic Bearings

-

Hybrid Ceramic Bearings

-

Silicon Carbide Bearing

-

Ceramic Sliding Bearing

-

Ceramic Roller Bearings

-

Ceramic Thrust Bearing

-

Advanced Structural Ceramics

-

Silicon Nitride Ball

-

Silicon Carbide Ball

-

Zirconia Ceramic Ball

-

Silicon Carbide Ball Bearings

-

Silicon Nitride Ball Bearing

-

Zirconia Ceramic Bearing

-

Mechanical Sealing

-

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years.

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years. -

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

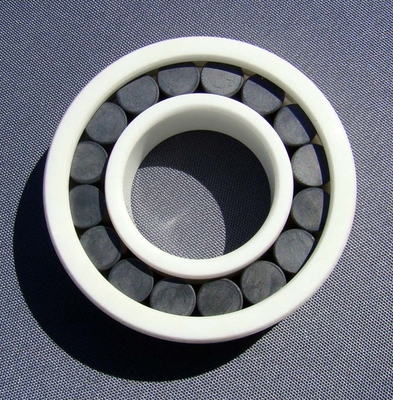

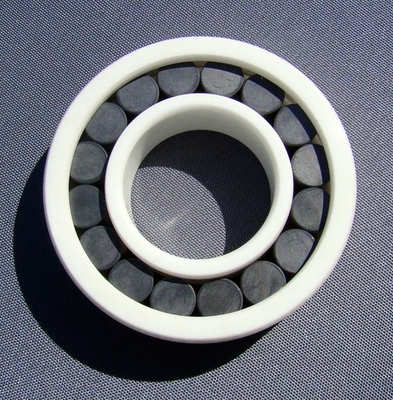

Full Cylindrical Ceramic Roller Bearings Si3N4 SSiC ZrO2

| Name | Full Cylindrical Ceramic Roller Bearing | Race Material | Silicon Nitride Or Silicon Carbide Or Zirconia |

|---|---|---|---|

| Roller Material | Silicon Nitride Or Silicon Carbide Or Zirconia | Precision | Customized, According To Your Requirement |

| Model | Customize | Pacage | Foam+cartom Box |

| Highlight | ZrO2 cylindrical roller bearing,cylindrical roller bearing ceramic full,ZrO2 roller bearing |

||

Full Cylindrical Ceramic Roller Bearings In Material Of Si3N4/SSiC/ZrO2

Description of Full Cylindrical Ceramic Roller Bearing:

Our company can customize full cylindrical ceramic roller bearings of all kinds of models according to your requirement. The material of races and rollers can be chosen among silicon nitride, silicon carbide and zirconia. Welcome your inquiry.

| Material Properties | Units | SSiC | HIP-Si3N4 | GPS-Si3N4 | HIP-ZrO2 |

| Density | g/cm3 | 3.15-3.18 | 3.27-3.29 | 3.22-3.27 | 6.05-6.09 |

| Porosity | % | 0 | 0 | 0 | 0 |

| Fledural Strength | MPa | 550 | 830 | 689 | 900 |

| Elastic Modulus | GPa | 410 | 310 | 310 | 200 |

| Hardness | HV5 | 2800 | 1580 | 1450 | 1300 |

| Fracture Toughness KIC | MPa.m1/2 | 4.6 | 6.1 | 5.7 | 8-11 |

| Maximum Use Temperature |

℃ |

1650 |

1000 |

1000 |

380 |

![]()

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews