-

Ceramic Ball Bearings

-

608 Ceramic Bearings

-

Hybrid Ceramic Bearings

-

Ceramic Roller Bearings

-

Ceramic Thrust Bearing

-

Ceramic Sliding Bearing

-

Advanced Structural Ceramics

-

Silicon Nitride Ball

-

Silicon Carbide Ball

-

Zirconia Ceramic Ball

-

Silicon Carbide Ball Bearings

-

Silicon Nitride Ball Bearing

-

Zirconia Ceramic Bearing

-

Mechanical Sealing

-

Silicon Carbide Bearing

-

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years.

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years. -

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

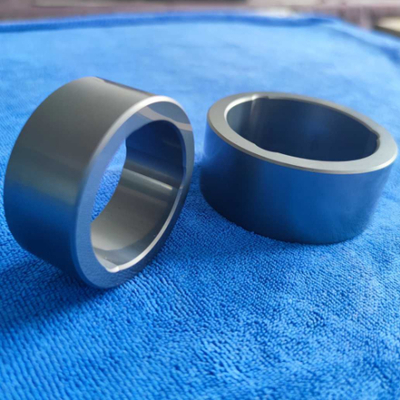

Customized SSIC Ceramic Sliding Bearing Sleeve 1650℃ Max Temp

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Customized Ceramic Sliding Sleeve Bearing | Category | Ceramic Sliding Bearing |

|---|---|---|---|

| Material | Pressureless Sintered Silicon Carbide | Size | Customized, According To The Drawings |

| Quality | High Precision, Long Life, OEM Serive | Corrosion Resistance | High |

| Friction | Low | Durability | High |

| Use | A Variety Of Pumps | Package | Foam+carton Box |

| Highlight | Customized SSIC ceramic bearing sleeve,Ceramic sliding bearing for pumps,SSIC bearing sleeve with warranty |

||

Silicon carbide sleeves serve as high-performance plain bearings, primarily utilized in shield pumps and magnetic pumps for fluid transfer applications. These components are also adaptable to various other industrial systems requiring exceptional wear resistance and thermal stability.

Silicon carbide ceramic demonstrates exceptional properties:

- Mechanical Performance: High strength, extreme hardness, and superior elastic modulus

- Thermal Characteristics: Excellent thermal conductivity coupled with low expansion coefficient

- Specialized Attributes: Outstanding specific stiffness and precision machinability

| Max Temperature | up to 1650℃ |

| Density | 3.15-3.18 g/cm³ |

| Thermal Expansion | 4.0 (10-6/℃) |

| Thermal Conductivity | 120 W/m°K |

| Hardness | 2800 HV5 |

| Elastic Modulus | 410GPa |

| Chemical Stability | Superior resistance to acid and alkali corrosion (including hydrofluoric acid) |

- Chemical & Petrochemical Industry:

- Media transfer pumps: Used in seal-less pumps (canned motor pumps, magnetic drive pumps) for corrosive fluids

- Reactor agitator shaft support: Resistant to high-temperature, high-pressure corrosive environments

- Semiconductor & Electronics Manufacturing:

- Lithography machine motion stages: Ultra-low thermal expansion ensures nanometer positioning accuracy

- Vacuum robot arm bearings: Non-magnetic, particle-free operation

- Heavy Machinery:

- Machine tool spindles: Reduces friction for higher machining accuracy

- Mining equipment wear parts: Resists slurry abrasion

Our company (ZXSQ/CSQ) possesses eleven invention patents for utility models. With a high-quality professional team of dozens of members, we provide customized bearing solutions according to customer requirements.

Since 1982, we have accumulated over 40 years of experience in ceramic bearing material research and development, continuously improving our processing techniques and equipment.

Through continuous evolution, we have become a leading enterprise in China's domestic market for ceramic bearing and ceramic material products.

We operate a fully automatic grinding and assembling production line for ceramic bearings, with an annual output of 3 million sets (including 608-2PS, 608-2RS and other specifications at P5 and P4 precision levels).

Our facility includes a rolling bearing 608 automatic production line, specializing in various types of rolling bearings, ceramic balls, and ceramic rollers.

Our firing equipment and technology lead the industry, featuring:

- Hot isostatic sintering furnace (HIP) imported from ABB Sweden

- Other high-end production equipment in industrial ceramics

- Product firing temperature capability exceeding 2000℃

We specialize in bearing research, development, production, and sales, providing high-quality bearing products and technical services. Using premium raw materials, we carefully craft each bearing set to meet exacting standards.

Customer needs guide our operations as we strive to deliver quality products and excellent after-sales service. We welcome the opportunity to discuss potential cooperation!