All Products

-

Ceramic Ball Bearings

-

608 Ceramic Bearings

-

Hybrid Ceramic Bearings

-

Ceramic Roller Bearings

-

Ceramic Thrust Bearing

-

Ceramic Sliding Bearing

-

Advanced Structural Ceramics

-

Silicon Nitride Ball

-

Silicon Carbide Ball

-

Zirconia Ceramic Ball

-

Silicon Carbide Ball Bearings

-

Silicon Nitride Ball Bearing

-

Zirconia Ceramic Bearing

-

Mechanical Sealing

-

Silicon Carbide Bearing

-

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years.

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years. -

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Contact Person :

Cooper wang

Phone Number :

86 15801087509

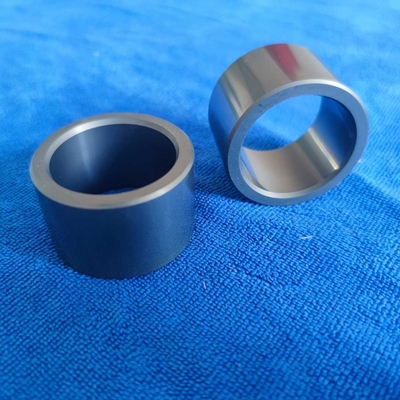

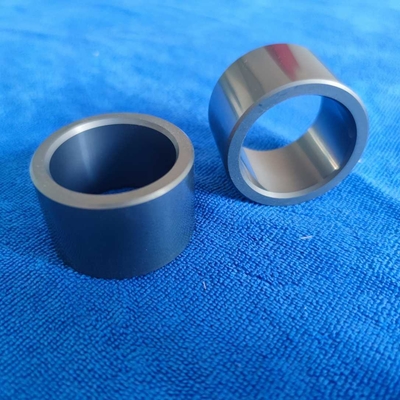

Customized SSIC Sliding Bearing Sleeve for Pumps, 1650℃ Max Temp

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Name | Customized Ceramic Sliding Sleeve Bearing | Category | Ceramic Sliding Bearing |

|---|---|---|---|

| Size | Customized,according To The Drawings | Material | Pressureless Sintered Silicon Carbide/Zirconia |

| Application | Pumps | Package | Foam+carton Box |

| Quality | High Precision, Long Life, OEM Serive | Specification | Standard Size And Customized |

| Highlight | Customized SSIC sliding bearing sleeve,Ceramic sliding bearing for pumps,SSIC pump bearing with warranty |

||

Product Description

Customized SSIC Pressureless Sintered Sliding Bearing Sleeve For Pump

Customized Silicon Carbide Sliding Bearing Sleeve

Engineered from premium-grade silicon nitride (Si3N4), silicon carbide (SiC), and zirconia (ZrO2), our ceramic sliding bearings outperform conventional steel bearings with exceptional durability and reliability. These high-performance components are specifically designed to withstand extreme conditions, including corrosive environments, elevated temperatures, and intensive wear scenarios, making them ideal for demanding industrial, automotive, and aerospace applications.

Key Advantages

- Extreme Corrosion Resistance - Withstands harsh chemicals, acids, and marine environments, ideal for chemical processing, pumps, and offshore equipment.

- Ultra-Low Friction & Wear - Smoother, harder ceramic surfaces minimize friction, reducing energy loss and extending bearing lifespan by 5-10X over metal alternatives.

- High-Temperature Stability - Operates reliably up to 1,400°C, perfect for turbines, engines, and industrial furnaces.

- Lightweight & Non-Magnetic - Reduces rotational inertia and eliminates magnetic interference, critical for aerospace and medical devices.

Applications

Ceramic bearings can be widely used in aviation, aerospace, navigation, petroleum, chemical, automotive, electronic equipment, metallurgy, electric power, textile, pump, medical instruments, scientific research and national defense and other fields, is the application of new materials of high-tech products.

Properties

| Max Temperature | up to 1650℃ |

| Low density | 3.15-3.18 g/cm3 |

| High strength | Excellent structural integrity |

| Low thermal expansion | 4.0 (10-6/℃) |

| High thermal conductivity | 120 W/m°K |

| High hardness | 2800 HV5 |

| High elastic modulus | 410GPa |

| Chemical stability | Superior resistance to acid and alkali corrosion (including hydrofluoric acid) |

Advantages of All-Ceramic Bearings Compared with Steel Bearings

- Higher temperature tolerance: Maintains mechanical properties at elevated temperatures.

- Better performance with temperature fluctuations: Smaller thermal expansion coefficient provides more stable clearance.

- Improved anti-bite and anti-stuck performance: Reduced thermal deformation enhances operational reliability.

- Oil-free operation possible: Self-lubricating characteristics suitable for high vacuum environments.

- Resistant to acid, alkali and salt corrosion: Ideal for chemical processing applications.

- Electrical insulation: Non-conductive properties eliminate static electricity issues.

- Non-magnetic: Prevents magnetic particle accumulation in sensitive environments.

Why Choose Us

Our Factory and Processing Machine

We have three factories in China to meet different customer needs, equipped with advanced pressing, sintering and processing machines. Our company (brands ZXSQ and CSQ) holds eleven invention patents and maintains a professional team dedicated to producing high-quality custom bearing products.

Since 1982, we have accumulated over 40 years of experience in ceramic bearing material research, development, and production. Our continuous improvement in processing techniques and equipment has established us as a leading enterprise in China's ceramic bearing market.

We have extensive experience producing both external and internal gear pump sliding bearings in silicon carbide material, including long-term supply to Germany's Witte company.

Our Bearing Advantages

- Free sample bearings available

- ISO Standard compliant

- In-stock bearings ready for immediate shipment

- Small order quantities accepted

- OEM bearing services

- Customized bearings from customer drawings or samples

- Competitive factory direct pricing

Frequently Asked Questions

Q: Who are we?

A: We are a factory in Beijing, China with over 40 years of experience producing ceramic bearings, serving domestic and international clients.

Q: How can we guarantee quality?

A: We follow strict production protocols, conduct pre-production sampling, and implement precise inspection using specialized equipment. Our double-layer packaging (foam and carton) ensures product protection.

Q: What can you buy from us?

A: We offer ceramic deep groove ball bearings, angular contact ball bearings, hybrid ceramic bearings, linear bearings, and various ceramic balls.

Q: Why should you buy from us?

A: Our integrated production and trade operations across three factories enable better quality control, competitive pricing, and reliable delivery schedules.

Q: What services do we provide?

A: We offer high-quality products, full customization, sample confirmation, and responsive customer service tailored to specific requirements.

Welcome Your Enquiry

We maintain strategic partnerships with raw material suppliers to ensure consistent quality and pricing stability. Our in-house material production capability provides additional flexibility when needed. Customer-focused and committed to excellence, we strive to be your reliable partner for ceramic bearing solutions. Contact us today to discuss your requirements.

Recommended Products