-

Ceramic Ball Bearings

-

608 Ceramic Bearings

-

Hybrid Ceramic Bearings

-

Silicon Carbide Bearing

-

Ceramic Sliding Bearing

-

Ceramic Roller Bearings

-

Ceramic Thrust Bearing

-

Advanced Structural Ceramics

-

Silicon Nitride Ball

-

Silicon Carbide Ball

-

Zirconia Ceramic Ball

-

Silicon Carbide Ball Bearings

-

Silicon Nitride Ball Bearing

-

Zirconia Ceramic Bearing

-

Mechanical Sealing

-

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years.

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years. -

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

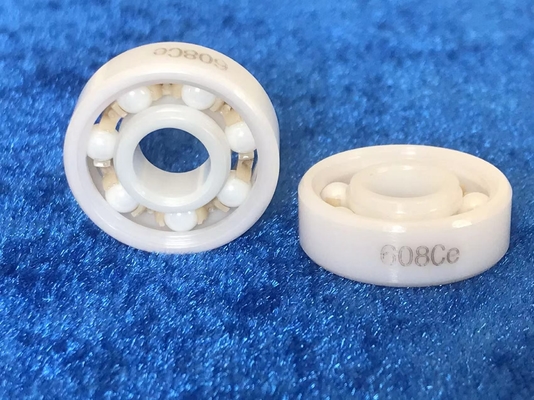

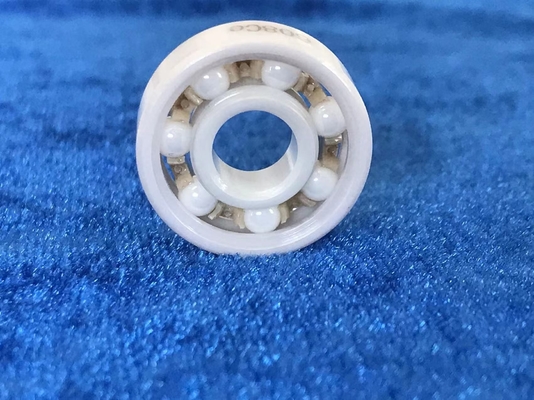

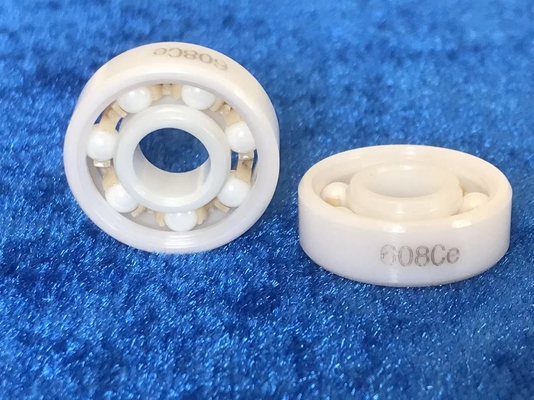

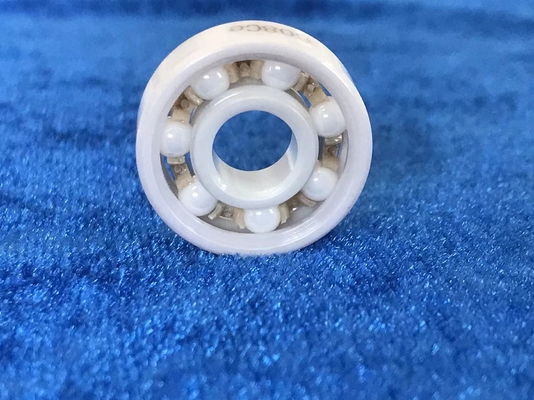

Popular 608ce Miniature Ceramic Bearing Zirconia For Skate Board

| Place of Origin | Tianjin, China |

|---|---|

| Brand Name | CSQ |

| Certification | FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001 |

| Model Number | 608ce |

| Minimum Order Quantity | 20-50 pcs (negotiable) |

| Price | negotiable |

| Packaging Details | Foam+carton box |

| Delivery Time | 20-45 work days(negtiable) |

| Payment Terms | T/T |

| Supply Ability | 2000 pcs per month |

| Size | 8 X 22 X 7 | Cage | Nylon/Peek/PTFE |

|---|---|---|---|

| Precision Grade | P6/ABEC3 To P4/ABEC7 | Feature | High Wear Resistance |

| Application | Skateboard, Roller Skate | Sample | Available |

| Highlight | 608ce miniature ceramic bearing,skate board miniature ceramic bearing,608ce high speed ceramic bearing |

||

As an important basic component of machinery, ceramic bearings have been increasingly widely used due to their excellent performance that cannot be matched by steel bearings.

Ceramic bearing characteristics:

1. Since ceramic is corrosion resistant, ceramic bearings are suitable for working under the harsh conditions of corrosive media.

2. Because the density of ceramic rolling ball is lower than steel, the weight is much lighter, so the rotation of the centrifugal effect on the outer ring can be reduced by 40%, and thus the service life is greatly extended.

3. Ceramic is less affected by thermal expansion and contraction than steel, thus allowing the bearing to work in environments with more drastic temperature changes when the clearance of the bearing is certain.

4. As the modulus of elasticity of ceramic is higher than steel, it is not easy to be deformed when it is subjected to force, so it is conducive to improving the working speed.

![]()

608ce Applications

►Skateboard--self-lubrication

![]()

►Roller skate--high rotating speed

![]()

Our Factory

•Certifications

![]()

•Production Lines and Inspection Equipment

![]()

•Why choose us

We have three factories in China, can meet the needs for different customers, and also we have advanced pressing, sintering and processing machines. Our company has specialized production of high-precision ceramic ball production line, as well as ceramic bearing grinder, automatic assembly production line. In addition, our HIP sintering furnace from Sweden ABB company, so we are confident that you will be satisfied with our products.

![]()

![]()

•FAQ

1. Q:What the MQQ of your company?

A:MQQ is 20-50 pcs.

2. Q:Could you accept OEM and customize?

A:YES,we can customize according to your sample or drawing.

3. Q:Could you supply sample for free?

A:Yes,we can supply sample for free, but not charge the freight.

4. Q:Does your factory have any certificate?

A:yes.we have FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001.

5. Q:IS you company factory or Trade Company?

A:We are the supplier and we have our own factory.

6. Q:Could you tell me the material of our bearing?

A:We have ZrO2(Zirconia), Silicon Carbide(SSiC), Silicon Nitride(Si3N4), Aluminia(Al2O3).

7. Q:Could you offer door to door service?

A:Yes,by express(DHL,FEDEX,TNT,UPS.)

8. Q:Could you tell me the payment term of your company can accept?

A:T/T.

9. Q:Your factory how to control the quality?

A: All bearing parts before the production and the production process, strict inspection by 100%, including crack detection, roundness, hardness, roughness, and the geometry size, all bearing meet ISO international standard.

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews