-

Ceramic Ball Bearings

-

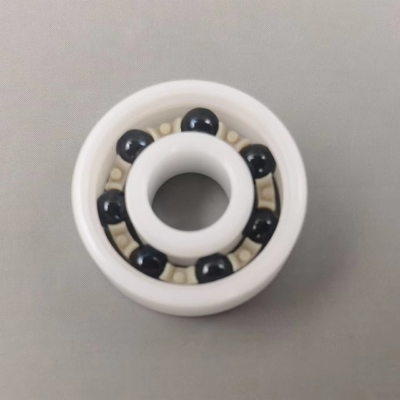

608 Ceramic Bearings

-

Hybrid Ceramic Bearings

-

Silicon Carbide Bearing

-

Ceramic Sliding Bearing

-

Ceramic Roller Bearings

-

Ceramic Thrust Bearing

-

Advanced Structural Ceramics

-

Silicon Nitride Ball

-

Silicon Carbide Ball

-

Zirconia Ceramic Ball

-

Silicon Carbide Ball Bearings

-

Silicon Nitride Ball Bearing

-

Zirconia Ceramic Bearing

-

Mechanical Sealing

-

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years.

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years. -

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Abec 9 608 Ceramic Bearings For Fishing Reels

| Name | All Ceramic Bearing 608 | Category | Ceramic Ball Bearing |

|---|---|---|---|

| Material | Zirconia Races+HIP-Silicon Nitride Balls+peek Cage | Precision | P6/ABEC3 To P4/ABEC7 |

| Diamater | 8×22×7mm | Ball | Hot Isostatic Silicon Nitride Ball Of 3.969 Mm |

| Use | Fishing Reel | Pacage | Plastik Box+carton Box |

| Highlight | 608 bearings abec 9,abec 9 fishing reel bearings,full ceramic fishing reel bearings |

||

608 All Ceramic Bearings For Fishing Reels, ZrO2 Races+HIP-Si3N4 Balls+Peek Cage

Description of All Ceramic Bearing 608 ( HIP-ZrO2 Races+HIP-Si3N4 Balls+Peek Cage):

1. HIP-ZrO2 races: Are made by highly purified, sub-micron and after Y2O3-TZP stabled zirconia powder material, are processed by AP (Atmospheric Pressure) sintering and HIP (Hot Isostatic Pressure) sintering technology, so their porosity, wear resistance, impact resistance and resistance to fatigue contact life are greatly improved.

2. HIP-Si3N4 Balls: Are made of highly purified, submicron silicon nitride powder with an alpha phase of more than 92%, and is processed by GPS (Gas Pressure) sintering and HIP (Hot Isostatic Pressure) sintering technology. Compared with GPS sintered silicon nitride material, the porosity, wear resistance, crushing value and fatigue contact life of after HIP sintered sinlicon nitride have been greatly improved, which is the preferred material for ultra-high speed and high precision ceramic bearings.

3. PEEK cage: The crown structure cage is adopted British Victrex PEEK material and injection molded at high temperature, so have high strength, light body, and will be fitted to the bearings using our unique design of press-fit double-sided construction. PEEK material has similar corrosion resistance to ceramic materials, and has a good resistance to radiation, self-lubricating properties, a high degree of wear resistance and other characteristics.

Performance advantages of All Ceramic Bearing 608 ( HIP-ZrO2 Races+HIP-Si3N4 Balls+Peek Cage):

With the properties of zirconia and silicon nitride, the bearings have high hardness Hv1280, wear resistance, resistance to various strong acids, strong alkalis, salt corrosion (except hydrofluoric acid), non-magnetic, non-conductive, high temperature resistance, high operating speed, impact resistance and small volume density, light weight structure, resistance to dry friction, low coefficient of linear expansion, self-lubrication, high fatigue life.

Main application of All Ceramic Bearing 608 ( HIP-ZrO2 Races+HIP-Si3N4 Balls+Peek Cage):

Because of the above mentioned performance advantages, all ceramic bearing 608 with this kind of material combination are widely used in fishing reels,especially the trolling reels.

| ►Key properties of zirconia |

| ♦ Max Temperature up to 380℃ |

| ♦ High density: 6.09 g/cm3 |

| ♦ Low thermal conductivity |

| ♦ Chemical stability, resistance to acid and alkali corrosion |

| ♦ High fracture toughness KIC:8-11 MPa-m1/2 |

| ♦ Good electric insulation |

| ♦ Better bearing capacity |

| ♦ Wear resistance |

| ♦ High hardness : 1300 HV5 |

| ► Key properties of hot isostatic sintered silicon nitride |

| ♦ Max temperature to 1000℃ |

| ♦ High strength over a wide temperature range |

| ♦ High fracture toughness: 6.1 MPa-m1/2 |

| ♦ High hardness: 1580 HV5 |

| ♦ Outstanding wear resistance, both impingement and frictional modes |

| ♦ Good thermal shock resistance |

| ♦ Good chemical stability,resistance to acid and alkali corrosion |

| ♦ Good electric insulation |

![]()

![]()

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews