-

Ceramic Ball Bearings

-

608 Ceramic Bearings

-

Hybrid Ceramic Bearings

-

Ceramic Roller Bearings

-

Ceramic Thrust Bearing

-

Ceramic Sliding Bearing

-

Advanced Structural Ceramics

-

Silicon Nitride Ball

-

Silicon Carbide Ball

-

Zirconia Ceramic Ball

-

Silicon Carbide Ball Bearings

-

Silicon Nitride Ball Bearing

-

Zirconia Ceramic Bearing

-

Mechanical Sealing

-

Silicon Carbide Bearing

-

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years.

RobertaTheir ceramic bearings are of high precision, good quality and inexpensive. We do have cooperation for many years. -

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

Olga WeinbergThis company is our reliable and professional supplier of ceramic bearings for many years, their ceramic bearings, which are used in our pump are good in quaility.

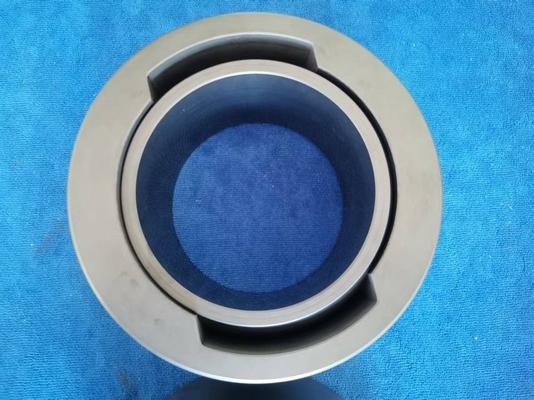

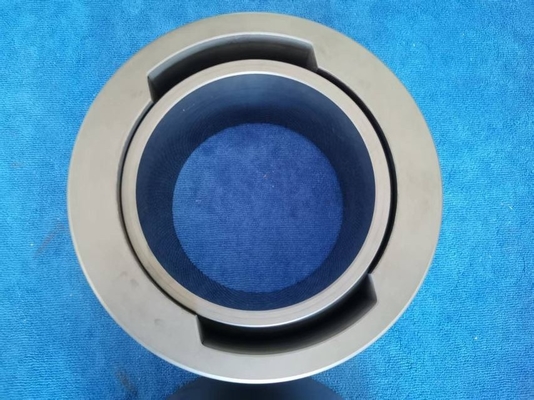

High Performance SSIC Ceramic Bearing For Optimal Functionality And Durability In Machinery

| Place of Origin | China |

|---|---|

| Brand Name | CSQ |

| Certification | FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001 |

| Model Number | customized |

| Minimum Order Quantity | 50 PCS (negotiable) |

| Price | According to the material and amount. |

| Packaging Details | Foam+carton box |

| Delivery Time | 30-45 works day |

| Payment Terms | T/T or Paypal |

| Supply Ability | 10,000 pcs per month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Features | High-Speed, Solid, Light Weight, Flexibility | Name | SSIC Ceramic Joint Bearing |

|---|---|---|---|

| Material | Silicon Carbide | Category | Ceramic Bearing |

| Use | Electric Handpieces For Dental | Application | Pumps |

| Highlight | SSIC Ceramic Bearing,Machinery Ceramic Bearing,High-Performance Ceramic Bearing |

||

| Attribute | Value |

|---|---|

| Name | SSIC Ceramic Joint Bearing |

| Material | Silicon carbide |

| Category | Ceramic Bearing |

| Features | High-Speed, Solid, Light Weight, Flexibility |

| Use | Electric Handpieces For Dental |

| Application | Pumps |

Ceramic Joint Bearings are widely used in lower-speed swing, tilt and rotation movement. They feature anti-corrosion properties, resistance to wear, self-aligning capability, good lubrication or self-lubricating with no lubrication dirt pollution, and can even work under misalignment conditions.

Core Mechanism: Ceramic Joint Bearings operate on a sliding-contact principle, where the spherical inner ring rotates or oscillates within the outer ring (socket), enabling:

- Multi-directional movement: Simultaneous rotation, tilting (±3° to ±10°), and axial displacement

- Self-alignment: Automatically corrects shaft misalignment caused by mounting errors or structural deflection

- Construction Machinery: Excavator arm joints, hydraulic cylinder mounts

- Aerospace: Landing gear steering, flight control surfaces

- Automotive: Suspension linkages, steering knuckles

- Wind Energy: Pitch/yaw systems in turbines

- Medical: Orthopedic joint implants

Our Ceramic Ball Bearings are engineered to provide superior performance and reliability in high-speed and high-temperature applications. Our technical support team is available to assist with any questions or issues you may encounter with our product.

We also offer a range of services to ensure optimal performance including installation support, maintenance services, and training programs for your staff. Contact us to learn more about how we can support your business needs.

Product Packaging: Our Ceramic Ball Bearings are carefully packaged to ensure safe delivery. Each bearing is individually wrapped and placed in a sturdy, protective box to prevent any damage during shipping.

Shipping: We offer worldwide shipping. All orders are processed within 1-2 business days and shipped via reliable courier service. Estimated delivery time varies by location (3-14 business days). You will receive a tracking number once your order is shipped.